Self-made dvukhskatny greenhouse from a profile pipe

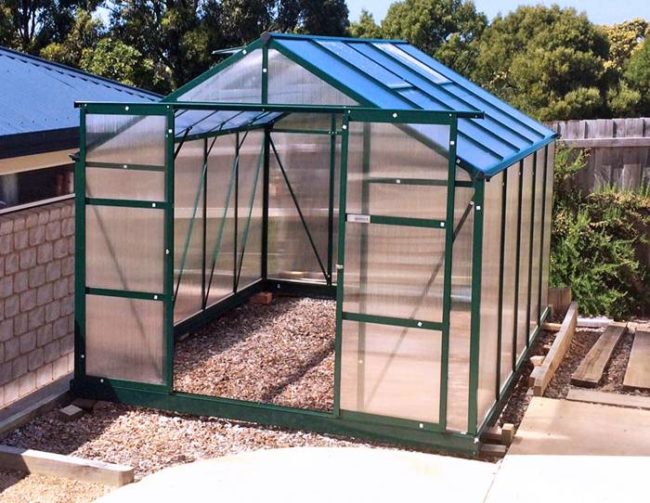

A greenhouse with a double-slope roof is not uncommon in home gardens. Make it on the frame of the profile pipe with your own hands every man can. For the successful implementation of the project, you can take ready-made published drawings or resize them. If there is not much experience in construction, detailed instructions for all stages with photos will be a great help in the work.

Advantages and design features

Duplex greenhouses have shown themselves well in different climatic conditions. For a variety of reasons, they are good for growing a wide variety of agricultural and ornamental crops in temperate climates.

- Resistant to wind and rain.

- Sufficient height for maintenance and cultivation of tall crops, greenery and flowers in several tiers.

- The space inside is devoid of uncomfortable and unsuitable for placing plants areas.

- With the same occupied area, the volume inside is larger than that of structures of a different shape - more air provides a good microclimate, a uniform change in temperature and humidity.

- It warms up and is well lit, with sufficient insulation can be used throughout the year.

- It is easy to calculate and design with a minimum amount of material scraps for the frame and the cover.

- Assembly does not require rare equipment - pipe bending machine. Even without a welding machine, you can do.

The main feature of the dual-slope greenhouse is the ability to change the height of the ridge. Usually the slope of the roof is about 30-40 degrees. If winters are snowy and there is no possibility to clean the roof, it is better to make it steeper so that the snow does not accumulate, but crawl under its own weight. In warmer climates and winters with little snow, it is convenient to install air vents in the roof.

Covered greenhouses in the form of a house can be:

- glass or pre-fabricated metal constructions with double-glazed windows;

- polyethylene film - for temporary seasonal constructions and light greenhouses;

- PVC film - more durable and modern;

- The most popular coverage option is polycarbonate - thanks to excellent light-transmitting and heat-insulating characteristics at a reasonable price.

Characteristics of the profile pipe

The profile pipe is a type of metal-roll from high carbon steel, formed with edges of standard width and a seam along the entire length. The main qualities of the profile pipe - resistance to corrosion and stress with low weight. Constructions from it can be assembled both by welding and using conventional fasteners - bolts with nuts, screws, brackets. Installation under the force of one person, the finished design can be moved around the site.

On sale there is a profile pipe with a galvanized coating, designed for installation without welding.

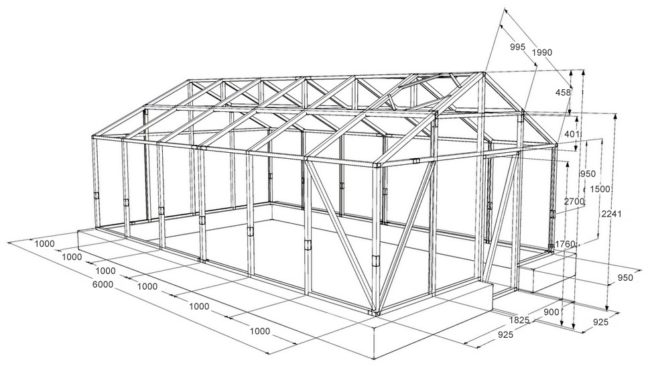

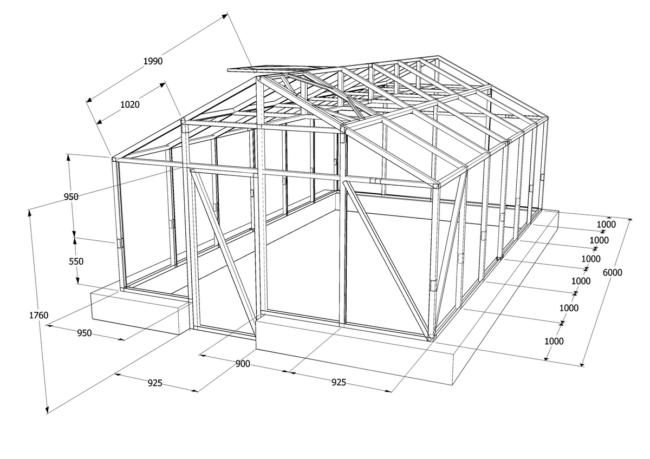

It is possible to assemble a seasonal collapsible greenhouse and a stationary winter one from a profile pipe. For mounting a small greenhouse with a coating of popular polycarbonate, a pipe with dimensions of 20x20 or 20x40 mm and a wall thickness of 1.5 mm is sufficient. For the base frame, it is better to take a thicker tube with a square cross section - 40x40 mm and a wall thickness of 2-2.5 mm.If you plan to sheathe the frame with heavier material, then you need to either take a thicker pipe, or make more stiffeners.

Do I need to make a foundation?

For an easy portable seasonal greenhouse there will be a fairly stable base from a wooden bar. For a more capital one, designed for the cold season or just a big one, you will need a foundation. Bookmark tape greenhouse foundations It is recommended to produce from the profile pipe in compliance with several mandatory steps.

- In a trench with a depth of 40 cm and a width of 20 cm, it is necessary to lay a gravel bed about 5 cm thick and level it. Formwork for the basement is installed above the ground.

- On a gravel pad, vertically install the sections of a thicker profile pipe, which will subsequently be located above the upper part of the foundation. They will be attached to the base of the frame. It is important that these pegs do not touch the soil - this will prevent early destruction from corrosion. You need to install about a meter away from one another, and in the corners - a couple.

- Pour the foundation together with the plinth and leave until it hardens for the allotted time, covered with foil.

- When the foundation gains final strength, a base must be attached to it. The easiest and most reliable way is to weld it to the reinforcement installed in advance in the foundation.

Features of the frame assembly x2

The frame of the profile pipe can be assembled with fasteners and welding. Welded joint more durable, not loosened. The fixture allows to dismantle the greenhouse for the winter or for some other reason. For the base, the front and rear walls, the base frame, engineers recommend taking a thicker pipe. For intermediate supports and additional stiffeners - easier.

- Collect need to start with the back end wall.

- Then assemble the front end wall.

Be sure to measure the length of the diagonals in the resulting framework. Diagonals must be strictly equal. This is the only reliable method to control the squareness of the structure.

- Install the front and rear walls, carefully aligning them vertically with a plumb line.

- Then install vertical stiffeners along the sides. They should be fixed in 1 m increments to the base and reinforcement of the foundation.

- Fix the upper part of the frame - parallel to the base, connecting the vertical supports.

- After the ridge to fasten the top of the roof.

- It is recommended to reinforce the roof with additional guides for more reliable coating resistance to loads.

How to bend the pipe?

If the greenhouse is not very large, and when designing it, the dimensions of standard pipe sections were taken into account, then vertical supports for the roof and walls can be made without cutting the pipe out of whole pieces. To bend the pipe to the desired angle at the junction of the roof to the wall, you need to measure and at this height make an incision with a grinder. The incised pipe is easy to bend to the desired angle, making a small effort. Fold should be fixed by welding.

Welding work

Welded frame stronger assembled with fasteners. Especially important is a good connection of parts of the frame for the greenhouse, which implies year-round use. For the manufacture of the frame of the profile pipe is sufficient minimum skills to work with welding equipment. To the construction did not lead, you need to weld the parts as if grabbing, without making long welds. To ensure that the back and front walls are identical, welding can be performed simultaneously by placing them on each other and securing them with clamps.

After the installation works - fixing the base to the fixture, installing the front and rear end walls, lateral stiffeners and final fastening of the frame with horizontal guides, it is necessary to perform anti-corrosion treatment. To do this, use a metal brush to clean the welding seams of scale and coat the entire frame with an anti-corrosion primer. After you can paint in any color you like.

Thoroughly clean the welding seams and the ends of the cut pipes should be also in order not to damage the coating with sharp metal burrs.

Greenhouse cover

The greenhouse of the profile pipe can be covered with temporary or permanent materials. Polyethylene and PVC films will not withstand the loads from precipitation in winter, therefore they are suitable only for temporary seasonal greenhouses. Polycarbonate is good for all-season use, so it is reasonable to cover the frame with them. Before installing polycarbonate, all joints and ends should be carefully sealed.

Cellular polycarbonate is attached vertically to the chambers for natural condensate drainage. All joints should be combined with the details of the frame. To prevent damage to the coating from thermal deformations, for mounting should be used bolts with thermal washers. After installation, the attachment points should also be treated with adhesive-sealant.

Dvukhskatnaya greenhouse - a simple and versatile facility for growing vegetables, herbs, flowers, preparing seedlings. It is quite spacious and comfortable for garden work. The frame of the profile pipe and durable insulating coating makes it suitable for use in summer and winter in a midland. You can do it yourself without having rare additional equipment or tools.