Polycarbonate greenhouse at home

Growing vegetables, flowers and herbs on your plot allows you to get an environmentally friendly harvest. Polycarbonate greenhouses create optimal growth conditions for crops. You can get results much faster when disembarking in covered structures than with the option of planting in open ground. Polycarbonate structures on the frame make it possible to grow plants regardless of the natural climatic features of the region.

- Advantages and disadvantages of the greenhouse of the profile and polycarbonate

- Types of polycarbonate for greenhouses

- Profile types and characteristics

- Design of polycarbonate greenhouses

- Dimensions

- The cost of polycarbonate greenhouses

- Choosing the shape of the greenhouse

- Making greenhouse from polycarbonate do it yourself

Advantages and disadvantages of the greenhouse of the profile and polycarbonate

Polycarbonate greenhouse is a frame made of metal profile, sewn up with a cellular transparent polymeric material. The design is characterized by the following advantages:

- tightness. Tightly fitted polycarbonate prevents cool air from entering the space and retains heat inside;

- availability. The material from which to build structures, you can easily buy on the commercial markets and in specialized stores;

- ease of erection. You can purchase ready-made kits, which can be assembled according to the manufacturer's instructions with the help of an improvised tool, or build a greenhouse according to your needs and abilities;

- lifetime. The construction on the frame, sewn polycarbonate, will serve you for at least 10-15 years. Classic greenhouses with plastic wrap or wired glass are often required to be repaired;

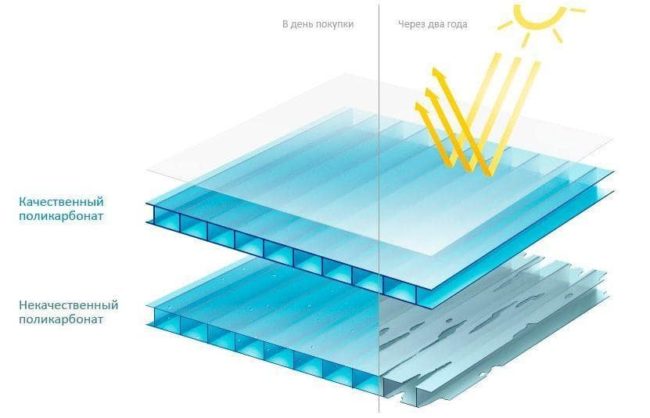

- high light transmission. Cellular polycarbonate transmits the entire spectrum of sunlight;

- resistance to temperature extremes. Plastic with polymer additives is capable of maintaining its quality at negative (up to -40aboutC) and high temperatures (up to +130aboutWITH);

- opportunity to increase the duration of the summer season with the installation of heating and lighting sources. The frame is able to withstand the weight of the lighting;

- quick disassembly. If you need to transfer the greenhouse to another place, you can easily disassemble the structure, transport it and build it on another site;

- low weight Profiles and polycarbonate sheets have a small mass, so you can build a greenhouse without a fundamental basis. The design can be easily transported without the involvement of special equipment;

- UV protection. In the production of polycarbonate used a special composition that prevents the penetration of ultraviolet rays;

- resistance of materials to aggressive substances. You can use insecticides or other pest control products inside the greenhouse.

- strength of covering material. Double plastic with polymer, the honeycomb inside the material, the air gap make polycarbonate reliable, well-preserving heat, flexible, easy to cut and install.

You can install a polycarbonate greenhouse on the frame of the pipe profile. The skeleton of such a material is able to withstand not only covering material, but also a load of more than 300 kg per 1 square meter. m

Comparison of greenhouses of their various materials is given in the table.

| Position | Polycarbonate | Film | Glass |

| Foundation | Does not require | Does not require | Necessary to avoid skewing |

| Frame | Available pipe profile that is easy to assemble into hardware or corners. The service life of at least 15 years. | A tree that requires regular repair and treatment of fungal infections. The service life is not more than 5 years. | Wooden frames that have a high weight. Requires reliable bonding between the segments. The service life of 5-7 years with regular care. |

| Covering material | Flexible, durable, wear-resistant polycarbonate resistant to mechanical damage. Service life not less than 10-15 years. | Cheap and affordable material - polyethylene. It simply stretches onto the skeleton and is fastened with the help of slats and studs. Service life - 1 year. It is required to buy and sew each frame with new polyethylene every season. | Glass very fragile covering material that is easily damaged by mechanical action. With the spring movement of the soil, natural phenomena (hail, strong wind, heavy rain) can break or crack. High care is required when working inside the greenhouse so as not to damage the wall garden tools. |

| Cost of | Depending on the area, form of construction and thickness of polycarbonate, the price is 20-30 thousand rubles. | The cost of building a greenhouse will be from 4 thousand rubles. | With using old window frames with glass you need to fill tape foundation. The cost of the base - from 5 thousand. Requires annual glazing of the roof with glass or greenhouse film. |

It is economically profitable to invest once in the construction of a polycarbonate greenhouse, which will serve you at least 15 seasons.

Types of polycarbonate for greenhouses

Manufacturers make sheet polycarbonate of various characteristics. The material is produced in accordance with the approved standard TU-2256-001-54141872-2006.

You can build a polycarbonate greenhouse of the following types:

- 2H is a double-layered material with a thickness of 0.4 to 1 cm with rectangular honeycombs. Available in 4 variations depending on the thickness of the polycarbonate;

- 3X - a three-layer polycarbonate 1.6 cm thick, the honeycombs of which have separate inclined stiffening ribs. The material due to the complex structure is more resistant to stress and mechanical damage;

- 3H - material of three layers of polymer sheets with rectangular honeycombs. It has a thickness of 0.6 to 1.6 cm;

- 5W - five-layer polycarbonate with a thickness of 2 cm with rectangular honeycombs;

- 5X - polycarbonate of 5 layers, each of which has a honeycomb with additional oblique stiffening ribs. The thickness of one sheet can reach 2.5 cm. It is able to withstand a load of up to 3.4 kg per square meter. cm.

The material is produced in sheets with a length of 6 and 12 m. The height of one panel has a size for all types of 2.1 m. Polycarbonate with marking 5X is produced with a height of 1.2 m.

Profile types and characteristics

The strength of the greenhouse and its service life depends on the reliability of the frame, which is sewn up with a covering material. The skeleton, which will last at least 15 years, is constructed from a metal pipe profile. It is necessary to choose products with galvanization. Galvanized pipe profile:

- has high strength;

- does not corrode;

- able to bend;

- easily cut by the tool;

- Zinc coating is able to create a new film that protects against corrosion.

The framework is constructed in various forms. Aluminum or steel galvanized steel pipe profiles have optimal characteristics for the construction of the villa's greenhouse construction. As a cheaper material for the construction of the frame, you can choose a wooden bar section of 30 x 30. Comparative characteristics of components for the construction of polycarbonate structures are shown in the table.

| Characteristic | Galvanized aluminum profile | Galvanized steel profile | Tree |

| Section | From 20 x 20, 30 x 30, etc. | From 20 x 20, 30 x 30, etc. | With a section from 30 x 30 |

| Mounting method | Hardware, corners | Welding, corners, hardware | Hardware, corners |

| Bending ability | High | Low | Very low |

| Weight | Small | Big | Small |

| Corrosion Resistance | Resilient | Resilient | Resilient |

| Moisture resistance | Resilient | Resilient | Requires processing |

| Lifetime, years | 20 years | 30 years and more | 5-7 years |

| Price for the construction of the greenhouse 6 x 3 m | From 8 thousand rubles. | From 17 thousand rubles. | From 5 thousand rubles. |

The most easy to use aluminum profile. Competently assembled construction, reinforced with stiffeners, is able to withstand high loads and natural phenomena. To build the core of galvanized aluminum profile choose V, U or W-shaped products. The bend of each pipe profile provides rigidity to the structure. You can also use a square or pipe profile of cold and hot rolled products.

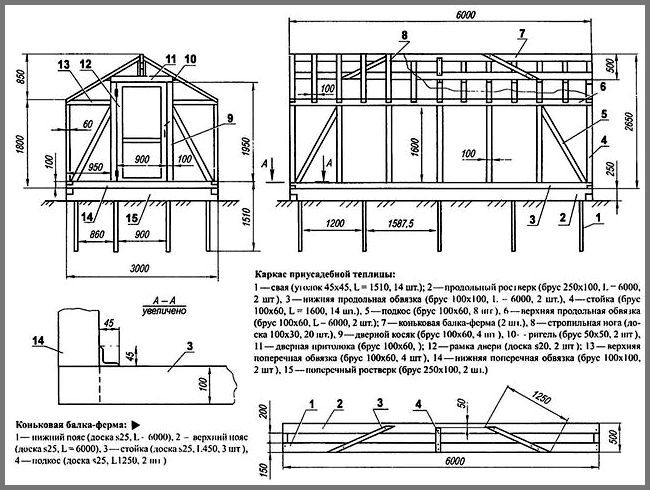

Design of polycarbonate greenhouses

Before the construction of the structure is necessary to make a sketch. This will help to make the calculation of the number of materials. Create a blueprint for the future structure in 3 projections. You can use graph paper. Draw a side view from the end and a top view with the application of dimensions, location of doors, stiffeners.

If you own computer programs for drawing and drawing, you can use the skill in designing a greenhouse.

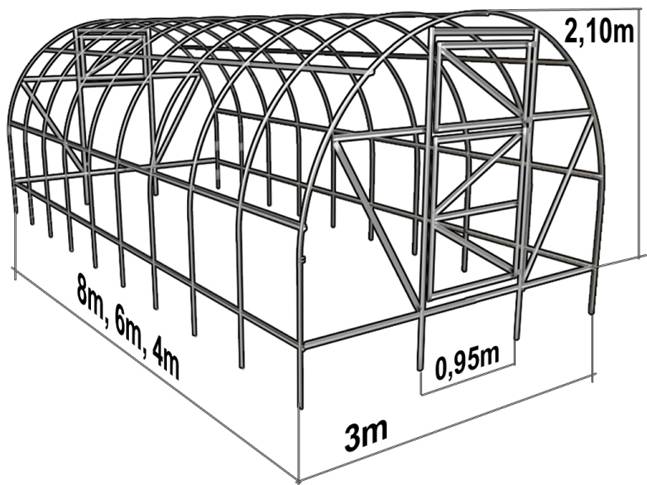

When building, consider that cellular polycarbonate is sold in sheets from 6 m and its width is 2.1 m. You can design a greenhouse of any size. Remember that a construction more than 3 m wide will require additional supports for the stability of the frame.

Dimensions

The greenhouse from sheet polycarbonate can be any sizes. Calculate how much you are willing to grow plants in the building. For the full growth of a single tomato bush, you need at least an area of 40 x 40 cm. You can equip a more efficient planting system according to the Metlider method.

When making a drawing of a polycarbonate greenhouse, use the following recommendations:

- the length of the longitudinal walls is more convenient to calculate a multiple of 2;

- Count the pillars at a distance of at least 1 m;

- point on the drawing stiffeners and their attachment points;

- To make the greenhouse taller than 2 m of the width of a standard polycarbonate sheet, use a base in the design and construction. You can put the structure on the basis of timber, brick or other material.

Breadbox greenhouses can be installed on the ridge boxes. This will save on material and implement the method of Meatlider. Most often gardeners build small greenhouses with a width of 2 m and a length of 3-4 m. Frame greenhouse structures, sewn with polycarbonate, are made for tall crops with a width of 3 m and a length of 6 m.

The cost of polycarbonate greenhouses

The total cost of building a polycarbonate greenhouse on its own plot depends on the size and materials. Ready-made kits that you only need to assemble, will cost more than a hand-built. The quality of components may be below expectations. Manufacturers offer assembly kits for various price lists.

| The form | Sizes, m | Frame | Polycarbonate thickness, cm | Estimated cost, rub. |

| Droplet | 2 x 4, center height 2 m | Galvanized tube profile 20 x 20 |

0,4 |

From 11,500 |

| Arched | 3 x 4, with a height in the working area of 2 m | Galvanized tube profile 20 x 20 |

0,6 |

From 15500 |

| Gable | 4 x 8, 2 m high | A framework from a galvanized profile 25 x 25 and stiffening ribs 20 x 20 |

1,6 |

From 26,000 |

| Gable | 3 x 6, 2 m high in the working area | Welded frame made of galvanized steel profile of rectangular cross section |

2,0 |

From 35,000 |

For hand-built, guided by the cost of materials and your drawing.

| Polycarbonate thickness, cm | Price per sheet 6 m, rub. |

|

0,4 |

From 2500 |

|

0,6 |

From 5000 |

|

0,8 |

From 7000 |

|

1,6 |

From 12,000 |

|

2,0 |

From 18,000 |

|

2,5 |

From 22,000 |

Metal pipe profile with galvanization costs from 130 rubles. for 1 m. The larger its cross section, the higher the price. It is also necessary to calculate the number and cost of fasteners. You should choose the metal screws for assembling the frame. When covering with polycarbonate, it is better to use hardware with rubber pads. This will ensure the tightness of the structure. Also do not forget about hinges for doors and vents.

Choosing the shape of the greenhouse

The shape of the structure on the frame, sewn polycarbonate, depends only on your preferences. You can build greenhouses in the form of:

- arches;

- droplets (domes);

- gable roof;

- polygonal shape;

- wall extension;

- razoskatnoy.

You can build a polycarbonate greenhouse of any shape and make it mobile. It is enough to attach wheels to the bottom base of the frame. You can also carry a lightweight construction on an aluminum frame. For this you need only a couple of people.

Depending on the materials, the greenhouse should be buried in the ground or fastened to a solid base.

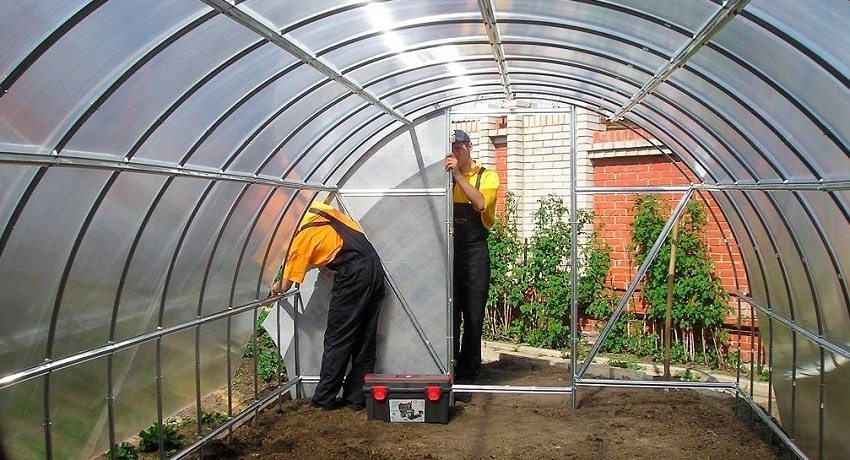

Arched

It is a structure in the form of an elongated transparent arch-tunnel. There is also another name for this design for greenhouses - "breadbox". The arch type greenhouse is installed on the frame in the form of arcs. The side walls can be straight, half the height of a man, and the roof of the building is installed on curved profiles. The advantages of the construction in the form of an arch is:

- ease of assembly;

- economical consumption of materials;

- resistance to strong wind.

Among the shortcomings it should be noted that in winter it is required to periodically remove snow cover from the structure. A gentle slope leads to a snow delay on the roof. Also for its construction is required to use a profile capable of bending. It will be problematic to build a steel pipe profile frame.

Dome

It has another name - "droplet". It is a small polycarbonate house, the roof of which is in the form of an elongated dome. The advantages of this type are:

- does not require snow cleaning in winter;

- large usable area.

The disadvantages include the complexity of the design. The upper part of the greenhouse is required to be built from a flexible profile.

Straight wall

The design has the form of a mini-house, assembled on a skeleton and sewn with sheet polycarbonate. The main advantages of the facility are:

- ease of construction;

- ease of settlement;

- large usable area;

- the ability to use as a frame of any material.

There should be a large slope of the roof to ensure the independent descent of snow.

Wall greenhouse

Most often has the form of a house with a single-pitch roof. It can be erected next to a residential house or an outbuilding with a shortage of free space on the site. Advantages of the wall greenhouse:

- saving on materials;

- simplicity of design;

- increased resistance.

The disadvantage of the wall construction is the lack of sunlight that plants will experience. It is recommended to build such greenhouses only on the south side. Most often these are narrow structures in which it is possible to make only one bed. Apply in them a method of growing crops according to Mitlayder.

Polygonal

The construction of broken lines, mounted on a rectangular frame, requires accurate calculations of the load. The advantages of the greenhouse are:

- the ability to work with the remnants of materials;

- the possibility of self-snow.

Among the shortcomings of the form, it is necessary to indicate the complexity of the construction.

Dvukhskatnaya

The construction is a hut elongated or just a gable roof, recessed into the ground. The advantages of the construction of this design are:

- speed of construction;

- economical consumption of materials;

- simplicity of calculations and construction.

The main disadvantage of this form is the lack of useful area for growing crops. Near the walls in the corners is possible only the cultivation of low-growing plants. However, access for care and watering will be difficult.

By mitlider

For growing according to the method of Mitlider fit any kind. The basis of the method is the creation of high beds, where plants will receive the maximum amount of nutrients through the root system. At the same time, care for cultures is simple and does not require much time.

Making greenhouse from polycarbonate do it yourself

Before construction, make a detailed drawing of the future structure with an indication of the size. This will help calculate how much a pipe profile or tree will be required to assemble the frame and the number of sheet polycarbonate.

Choosing a location

Greenhouse from polycarbonate can be built anywhere in the summer cottage. Do not choose areas near buildings, fences, and in the shade of large trees. It is better to choose a flat dry area. The construction of the structure on the slope is fraught with the impact on the walls of the structure the flow of water and melting snow. It is also possible that plants will experience a shortage of sunlight.

Consider the location of the sides of the world. It is necessary that the longitudinal walls are located parallel to the south.

The quality of the soil does not matter. You can fall asleep in the greenhouse, prepared for the cultivation of crops of the earth. Make a mixture of:

- 60% of garden land;

- 25% rotted manure;

- 5% wood ash;

- 10% peat.

Mix all the ingredients and pour into the greenhouse. As a result, you will receive a nourishing soil in which crops will receive all the substances necessary for growth and fruiting.

What tools and materials will be needed

For self-construction you will need polycarbonate in the amount necessary for stitching the frame. For mounting the core, it is necessary to prepare a pipe profile or a wooden block. Metal pipe-profile should have a cross section of at least 20 x 20 mm. Bars should be purchased with a size of at least 30 x 30 mm. Also prepare fasteners.

From the tools you need:

- shovel for leveling the site and the depth of the frame;

- hacksaw for cutting polycarbonate;

- building tape for exact lengths;

- Bulgarian or metal shears for cutting pipe profile;

- screwdriver for mounting sheets.

For the installation of polycarbonate should pick up screws with rubber washers or fasten hardware through improvised rubber gaskets.

Work should be carried out on a dry day after the snow melts. Already in April-May, you will be able to plant seedlings in a reliable modern greenhouse, which will serve you for at least 15 years.

The main stages of assembly

The construction of a polycarbonate greenhouse with their own hands is carried out in the following order:

- Clearing the site and construction of the base if necessary. Mark up with a rope and pegs.

- Cut from metal profile or wooden block pieces of the desired length for the skeleton. Use construction roulette, Bulgarian, scissors for iron or hacksaw.

- Assembling the frame with stiffeners. Use your sketch. All elements fasten on hardware, corners. Welding is possible for the installation of steel tube profiles. Start from the end wall. Finish mounting the roof.

- Strengthen the base of the frame in the ground. To do this, drill holes in which you place studs or pipes with a burial in the ground to a depth of at least 20-30 cm.

- Install the frame on the frame for doors and vents.

- Prepare polycarbonate pieces according to your prepared project.

- Sew the framed frame with polycarbonate pieces.

- Make the doors and vents, attach the fittings.

If there are gaps between the bottom of the greenhouse and the surface of the earth, they must be filled with soil.

Rules of working with polycarbonate and profile

The basic rule of working with polycarbonate is the consideration of the location of air cells. It is necessary that the cells are located vertically to the surface of the earth. The position of the honeycomb at an angle is allowed. If pieces of covering material are arranged horizontally, moisture can get into them. Slats should be installed between polycarbonate sheets that will prevent cool air from entering and heat leakage.

Profile is better to cut with an angle grinder (Bulgarian). Cutting with scissors can lead to the formation of chipping, bending of the profile edges. When working with metal profiles, use gloves and safety glasses. Make sure that you wear clothes made of non-combustible materials. Do not work near flammable liquids, children, animals.

The construction of a polycarbonate greenhouse will make it possible to create ideal conditions for growing different vegetables, flowers, and greens. For one season you can plant several types of plants in a design. By autumn, it is necessary to remove the tops, dig up the beds, add organic matter. In winter, depending on the design, it is necessary to ensure that a large amount of snow does not accumulate on the roof of the structure.