Self-made greenhouses from polycarbonate and plastic pipes

The greenhouse made of plastic pipes and polycarbonate will help you to get a rich harvest of your own vegetables, greenery, berries flowers. Construction of the construction of a master class with photos, drawings, diagrams will not cause difficulties even for people without special education. Simple lightweight polycarbonate buildings received a lot of positive feedback from summer residents with experience.

- Types of plastic pipes for greenhouse structures

- Greenhouse frame on the pipes

- The foundation for the greenhouse

- Greenhouse shape

- Calculation of materials and sizes

- Materials

- Instruments

- Assembly stages

- Nuances of working with pipes

- Features work with polycarbonate

- Ways to connect the frame and cover

- How to seal the design

- Reviews

- Conclusion

Types of plastic pipes for greenhouse structures

The assembly of the greenhouse structure consists of the construction of a frame made of pipes and the stitching of polycarbonate. For the skeleton of the greenhouse, you can use a variety of tube products. In the construction of indoor buildings for the cultivation of vegetables using a pipe profile made of metal, metal-plastic or polyvinyl chloride.

Metal pipe rolling requires treatment with anti-corrosion compounds; it is assembled into a framework only by welding and is heavy. Only a professional can build a greenhouse on the core of a cast-iron or steel pipe.

PVC or metal-plastic pipes have more advantages over rolled metal:

- pipe products from polymers with additives take any form. You do not need an additional tool to bend the frame elements;

- Do not need anti-corrosion treatment. Products at the production stage from inside and outside are treated with special compounds that protect against rust by spraying or dipping;

- resistant to temperature changes due to the composition of the alloy;

- withstand large mechanical without deformation changes;

- cheaper than metal pipe and wooden planed materials;

- just clipped with special mounts;

- have an aesthetically appealing look;

- ease of working with the material. PVC pipe profile is cut into pieces with a hacksaw, grinder, metal scissors;

- service life of about 50 years;

- characterized by low weight.

The skeleton of PVC or metal-plastic pipes can be picked up in a few hours. If necessary, the design is also easy to disassemble, move to another place, put in storage.

Greenhouse frame on the pipes

Prefabricated structures that are built from the assembled frame, for installation is not more difficult than the designer. Connection of pipe parts using special fasteners is easy, fast, and reliable.

The advantages of greenhouse structures built on a pipe frame are:

- small greenhouse weight;

- simplicity of work with materials;

- tightness of the building;

- strength of materials;

- the ability to create designs of any shape;

- affordable price;

- minimum tools and skills.

Metal-plastic or PVC-pipe for a long time does not collapse, can not be deformed, retains its characteristics. With timely repair and maintenance greenhouse design will last at least 40-50 years. Unlike iron pipe products, PVC does not need additional treatment from corrosion.

When designing the frame, please note that the bearing elements should be located at a distance of 70-100 cm from each other. For two- and single-sloping forms of greenhouse constructions, consider installing stiffeners.

The foundation for the greenhouse

The hothouse construction on the basis of the core of polyvinyl chloride pipes and polycarbonate weighs from 80 kg, depending on the size. The pipe frame of the medium-sized greenhouse has a mass of 50 kg. The construction does not need to build a strong foundation.

For the construction of the greenhouse structure on the frame of plastic pipes, sewn polycarbonate canvas, choose one of the types of the base:

- wooden tier. For installation of the foundation, a 15x15 or 20x20 bar can be used. Place the crown on the leveled surface in a small recess 10 cm. Fasten the skeleton of the greenhouse to the stone box with brackets, curved hardware, nails or installation of reinforcement in the bar body. Treat the base with antiseptic impregnation to prevent the wood from rotting under the influence of moisture;

- metal grillage. Use a channel, cast iron pipe or rail. Lay the base of the metal. The material requires regular anti-corrosion treatment. The frame of the greenhouse is fixed to the foundation by strapping with wire.

For setting polycarbonate greenhouses, select the flat areas. On slopes, the installation of a structure will require a leveling foundation.

Lightweight greenhouse construction needs weighting down to withstand gusty winds. You can not use any base when attaching the frame to the ground with the help of long studs embedded in the soil.

Greenhouse shape

The skeleton of a plastic pipe can be constructed of any shape. The greenhouse structures of their polycarbonate on the tube frame can be:

- arched;

- gable;

- single-pitch;

- complex configuration.

The easiest way to build an arched greenhouse. PVC or metal-plastic pipe profiles are easily bent into an arc, on top of which a flexible polycarbonate sheet is attached effortlessly.

Calculation of materials and sizes

The construction of a polycarbonate greenhouse begins with the design stage. Draw a schematic drawing of the future construction. A detailed drawing will help to calculate all the necessary details and make a construction estimate.

- When designing, display:

- construction regarding the site plan;

- type of construction from the end;

- top view of the greenhouse in the section.

In the figures, apply the dimensions of each element - the foundation, heights, lengths, the location of support arcs, doors, and windows for ventilation.

Materials

Based on the greenhouse project, estimate the calculations for the necessary materials. Detailed display on the sketch of all parts and sizes will make it easy to make calculations. The main items purchased material:

- PVC or Metloplastic pipe. Calculate how many pipe products you need for the construction of the frame, the installation of doors, windows;

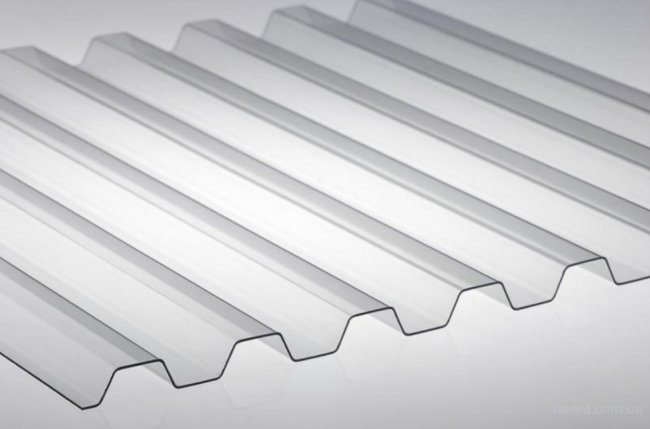

- polycarbonate. The minimum thickness for a greenhouse for covering material should be at least 15 mm;

- wooden block or metal material for the installation of the foundation;

- rope;

- landmarks or pegs;

- heck, locks, latches, door hardware;

- fasteners - metal screws, special fasteners for pipes, brackets, nails.

Depending on the design decision, consider the stiffeners, the number of doors and windows for ventilation.

Instruments

To build a greenhouse you will need the following list of tools and devices:

- building roulette;

- level;

- hacksaw;

- Bulgarian;

- hammer;

- screwdriver.

Pay attention to safety. Work in overalls, goggles, gloves, strong shoes.

Ensure that there are no pets and children in the assembly area of the greenhouse structure. When working with heat and sparks, conduct processes away from dry grass.

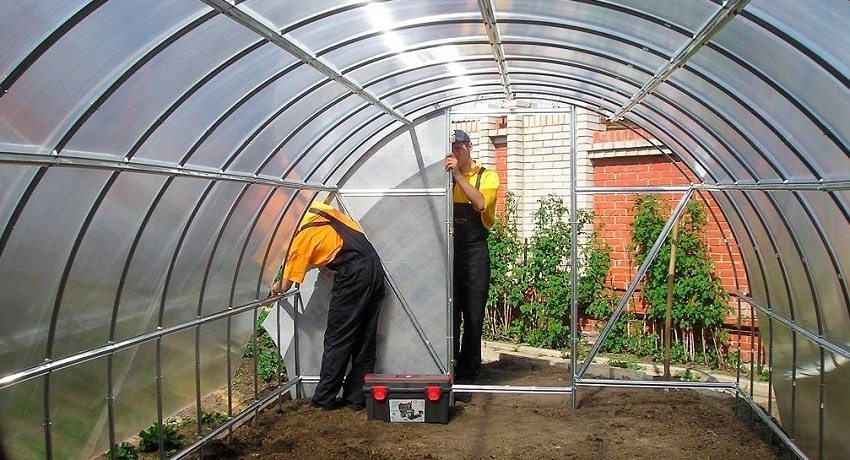

Assembly stages

The construction process after purchasing the required amount of building materials and creating a project, follow the following algorithm:

- pick a place under the greenhouse design. Choose a flat area, well lit by the sun;

- level the site for the installation of structures - remove the landing, ridges, dismantle the buildings, if necessary, backfill with soil or sand;

- make a markup on the territory with a rope and poles;

- install a base crown, if provided by the project;

- assemble the frame from tubular blanks in accordance with the planned form of construction;

- cut polycarbonate according to size;

- Sew a skeleton polycarbonate cloth;

- make doors and vents from plastic tubing and polycarbonate.

Start work in the morning. It is better to engage in construction in sunny weather. In just one day you will be able to build a greenhouse facility to grow your own crop.

Nuances of working with pipes

Depending on the shape of the greenhouse, cut PVC or metal-plastic pipes and cut them with a hacksaw or a grinder. Follow these guidelines:

- for arched greenhouses, build with arcs. Cut pipe products, insert into the pins mounted in the foundation layer, bending them, insert them into the reinforcement located on the opposite side. Place crossbars on top of the arcs to stiffen the structure;

- for pitched greenhouses, build using special hardware in the form of fittings or crosses. They can be in the form of a cross, a longitudinal cylinder, a corner, T-shaped;

- when cutting pipes, achieve perpendicular cut;

- Avoid chipping and jagged edges.

Doors and windows for ventilation should be assembled separately. Take into account the tight fit of the elements to each other to ensure tightness.

Features work with polycarbonate

When building a greenhouse structure on a frame wired with polymer carbonate, consider the following recommendations:

- proceed in the following order - first set up the core, take measurements, and only then start cutting the covering material;

- consider the location of the honeycomb in the covering material. Prevent ingress of precipitation inside;

- sew the greenhouse construction with polycarbonate canvas, pre-cut according to the removed dimensions;

- arrange polycarbonate elements tightly to each other or overlapped;

- fasten the sheets, observing the intervals between fasteners not more than 45-50 cm;

- use hardware with rubber washers. This is necessary for the tightness of the structure;

- cut off the end walls of the polycarbonate material with a punched tape, building compounds, sealants.

Ways to connect the frame and cover

Polycarbonate canvas on the assembled frame is fixed in different ways, which depend on the shape of the greenhouse. Cover material sewn up:

- joint to joint Polycarbonate, fitting to each other, is applied to the skeleton and fastened with hardware. Butt gaps in the future must be further closed to prevent heat leakage from the structure;

- overlap. The method is suitable for sewing large-sized pieces with a thickness of 1.5 cm. Overlap areas need additional coating for tightness.

In winter, shake the snow from the slopes or the arch so that a large amount of precipitation does not accumulate on the surface, increasing the load on the frame.

For mounting the covering material to the frame, choose hardware with wide caps. Additionally, lay a polymer washer between the fastener and the surface.

How to seal the design

The tightness of the structure is necessary to create a favorable climate inside the structure. Polycarbonate greenhouse on plastic pipes mounted in compliance with the following nuances:

- ground the base with soil and cover additionally with hay;

- the joints between the canvases covering material cover with a special tape;

- connections in corners and ends fill with sealant;

- ensure that the greenhouse box fits snugly to the foundation, glue the tape entering the grillage from below;

- in the manufacture of doors and windows, adjust the dimensions of the polycarbonate to fit the walls of the structure.

Hermetic protection of the polycarbonate greenhouse from the inside and outside will provide 35% longer heat retention inside. Reliably wired design will allow to grow crops from early spring to late autumn, and in the southern regions all year round.

Reviews

Egorov Sergey, 48 years old, Orenburg:

Previously, a film greenhouse was covered with my wife every year, it was very sorry for my work and the fact that the material was quickly torn, collapsed during frosts. We tried to sew polyethylene with reinforcement, but still the next year, the canvas becomes unusable. He put an arched structure on PVC-pipes on the bars, sewed polycarbonate. I regretted not having done this before. In such a greenhouse, vegetables grow faster; we sow greens in general as early as March-April.

Piskunova Nadezhda, 62 years old, Moscow region:

I try to provide my family with organic vegetables, I love to grow flowers. 3 years on my summer cottage greenhouse, assembled on plastic pipes and sewn polycarbonate. I can not get enough of her. In the film greenhouses, the plants will sometimes freeze or ripen, and in the new greenhouse the crop will grow like yeast. The money came out cheap, the construction itself was built by the son-in-law.

Povarova Zoya, 53, Pskov:

Our region is warm and I tried to start the crops early. I tried to grow cucumbers, tomatoes, greens and in film constructions and in glass from window frames. I had 2 greenhouses on the plot. Husband built a polycarbonate building a year ago in the form of an arch. We spent only 3 thousand on pipes and about 15 thousand on covering material. After I removed from one square of tomatoes in one season not 5-7 kg, as usual, but 10-12, we put on the site 2 more facilities for eggplants, peppers, greens and flowers.

Conclusion

Even a novice in construction can make a greenhouse out of plastic pipes and polycarbonate. Make a clear project, calculate materials, quickly and easily assemble the frame, sew it with a covering cloth. You will get a practical, durable, weather-resistant greenhouse construction for growing your own tasty, environmentally friendly fruits, herbs, and root crops.

Vadim

Dear author of the article, all those involved in polycarbonate know as 2x2 that PVC and polycarbonate are not “friendly”, in the places of contact in the polycarbonate sheets softening of the material will appear over time and then PVC will pass the polycarbonate where they adjoin.