How to make a greenhouse from plastic pipes with their own hands

In stores for gardeners, you can find any ready-made greenhouse, but it does not always correspond to the wishes of people. For this reason, many gardeners build such facilities on their own.

For greenhouse frames often use different types of plastic pipes. They are strong, do not rust and can take any form.

Types of greenhouse construction of pipes

Thanks to the practicality of the material to make a greenhouse is easy. On the garden plots there are different forms of greenhouse structures:

- arched;

- single slope (rectangular);

- gable (rectangular);

- wall (they are attached to the walls of buildings).

PVC pipe types are better

There are two types of plastic pipes. They are constantly used by gardeners. Rigid and straight greenhouse structures are erected from rigid pipes. Most often they look like small houses with gable roofs. The second type of material is flexible pipes made of polypropylene and polyvinyl chloride. They are suitable for creating beautiful arched structures.

You can build a spherical structure and even a greenhouse in the shape of a sphere from soft PVC pipes.

Any type of these materials is equipped with fittings. They connect the parts of the pipes together. Fittings are similar to tees, adapters and connectors when cornering.

We collect greenhouses from arcs

Greenhouses, collected from the arcs and canvases of covering material, are widespread in almost all…

Advantages and disadvantages of the material

Flexible and rigid PVC pipes have the following advantages:

- resistance to rust and corrosive processes. It is known that metal profiles always rust, and wood is unstable to moisture. This makes gardeners prefer plastic;

- ease of processing. The pipes are easy to cut, they can be bent in any direction;

- ease of assembly and disassembly;

- compactness and low weight during transportation;

- long service life - up to 50 years;

- resistance to temperature extremes and severe weather conditions;

- fire resistance (plastic is not subject to rapid ignition. It ceases to melt after the elimination of the source of ignition).

Among the shortcomings, the high cost of the material and the inconvenience of the structures purchased in the store are noted.

The choice of space on the site, the type and size of the greenhouse

The area on which the greenhouse is erected should be light, and the soil should be flat. It is necessary to decide in advance what time of year the greenhouse will be used. If you wish to grow plants and vegetables in the winter you should take care of the heating system. The type and size of the greenhouse is determined by paying attention to the shape, foundation and types of plants. It is better not to build a large greenhouse: it is costly. Maintaining optimal microclimate conditions is not easy - including, from a financial point of view.

The standard height of the greenhouse or greenhouse is 2 meters.

The width depends on the number of crops that will grow in the greenhouse. It is also determined, taking into account the door and the paths laid between the ridges.

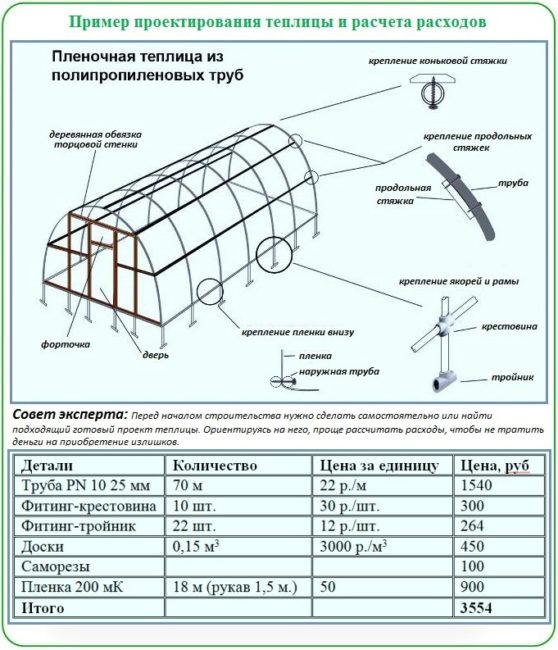

Calculation of materials and tools for work

First of all, determine the shape, length, height and width of the product.Inside the greenhouse there are two beds, between which a path is laid. If you plan the width of the beds from 0.8 to 1.1 m, you can plant the plants in two rows, observing the desired interval. Calculating the width of the aisle, it is necessary to take into account the value of gardening equipment. The standard path has a width of 0.6 to 0.8 m, with a total greenhouse width of 2.0 - 2.3 m.

First of all, determine the shape, length, height and width of the product.Inside the greenhouse there are two beds, between which a path is laid. If you plan the width of the beds from 0.8 to 1.1 m, you can plant the plants in two rows, observing the desired interval. Calculating the width of the aisle, it is necessary to take into account the value of gardening equipment. The standard path has a width of 0.6 to 0.8 m, with a total greenhouse width of 2.0 - 2.3 m.

The optimal length of greenhouses - from 3 to 6 m. If you put a large structure, it requires high strength materials and other installation technology. The length of the polycarbonate sheet to cover choose a multiple of its width. This will help save material. The height of the greenhouse should be such that it is not limited freedom of movement. Between the tops of vegetables, plants and flowers should be left half a meter wide for efficient air circulation.

Low vegetables (eggplants, peppers, certain types of tomatoes) grow well at a height of 1.80 cm to 2 m. For tall plants, you need to build a high greenhouse — from 2.30 cm to 2.4 m.

The distance between the arches also plays a big role. If the design is collapsible, you should adhere to the rules from 0.8 to 1 meter. If the owner wants to build a collapsible greenhouse, this value should be less: from half a meter to 0.7 m.

The small distance between the arches will save the undivided greenhouse from the severity of snow and deformation.

Also in the greenhouse are:

- doors;

- window vents;

- longitudinal screeds;

- end walls.

They also need to be considered when calculating the material. The length of the screeds is the length of the greenhouse, which is multiplied by their number. There are five design ties: two on the side, two on the bottom and one on the ridge of the roof. For more durable designs, install a few extra screeds on the sides.

You will need the following set of tools:

- drill or screwdriver;

- Bulgarian (for cutting polycarbonate);

- self-tapping screws;

- fasteners;

- building level (or level);

- hammer;

- nails;

- roulette.

Hotbed Snowdrop do it yourself

In the factory configuration, the greenhouse “Snowdrop” is a compact and corrosion-resistant building. Its width is 1.2 m and it is long ...

Assembly stages

Gather a greenhouse in several stages. First, prepare the site (with or without a foundation), then build the base and assemble the frame. After the frame is assembled, the frame is made and the structure is installed on the site.

Preparatory work

First, prepare the construction site. They remove the layer of soil from it. The area freed from turf should be greater than the future greenhouse by 1 m. This distance is necessary for a distance of 50 cm from either side. With the help of the construction level, the soil surface is measured and leveled.

For every 2 m of soil it is allowed to drop its height to 5 cm.

Base under the frame

After leveling the site you need to take 4 large boards. Dimensions are calculated in advance. For their bonding will be enough two or three strong self-tapping screws with galvanized. After assembly, the frame is installed on the site. It is fixed with four pieces of reinforcement, hammering them inside the corners. The length of the rods is from 70 to 80 cm.

Making a frame from plastic pipes

It will take a set of materials and accessories:

- polypropylene pipe;

- fasteners;

- several tees and corner adapters;

- self-tapping screws;

- metal rods for reinforcement (each is 0.8 m long).

It is necessary to place a rectangle on the section and drive rods along each long side of the figure. At the same time, the bars of the reinforcement are at a distance of 0.5 to 0.9 m. The depth of entry of the reinforcing bars into the ground is 40 cm. They should be located opposite each other. This will help avoid skewing.

Now pipes should be put on reinforcing bars on the opposite side. So, get a symmetrical arc. At the end of the installation of all the arcs, the pipe is laid horizontally so that it contacts the upper points of the arches. Secure the design with anchor bolts.

Covering of the arch greenhouse polycarbonate

Before sheathe a greenhouse with polycarbonate, it is important to know about the features of working with this material. The step between fastenings is observed in 45 mm, and all sheets are tightly joined to each other and fixed with a film. The mounting holes are drilled 1 mm larger than the dowel diameter.

In the process of fastening, use thermo washers: they increase the tightness of the structure.

The protective film is removed from the material only after the installation is completed. For mounting angular lines use a special angular profile. Before laying the sheet it is necessary to close its ends with tape and profile - for drainage and ventilation. This will ensure free flow of condensate. The ends can not be kept open or stick with a simple tape. When mounting the protective film should be facing out.

Installation on the foundation or in the ground

For installation of the greenhouse in the earth break the platform. It is marked with pegs. The size of the site is 4x9 m. Based on the dividing lines, the perimeter is determined to be 0.5-0.7 m. Now you need to plan the area inside the greenhouse, departing from the breakdown of 30 cm and drawing a line. On this line dig a trench. The line is its outer edge. The trench width is 40 cm and the depth is 30 cm. The bottom of the pit is slightly trampled down. Strongly ram the soil is not worth it, since we are talking about light construction. The bottom should be strictly horizontal, so you need a building level. If there are distortions, they are aligned.

To protect future crops from insects and weeds, the external wall of the fossa can be lined with slate or roofing material. Since polycarbonate greenhouse is a light construction, it is not necessary to lay the foundation for it.

Plastic pipes - an excellent building material for the frame of the greenhouse. It is well treatable, so even a novice master can cope with it.