Cellular polycarbonate: from installation to maintenance

High-quality cellular polycarbonate for greenhouses and greenhouses - a pledge of durability of the structure. Due to its physical characteristics, the material is superior to glass and film. There are many advantages to the material.

Evaluate them will be the one who will not rush to purchase. The starting point will be a technical task or a list of requirements that must meet the greenhouse or greenhouse.

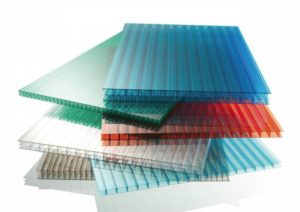

Kinds of cellular polycarbonate

Depending on the structure, the polymer material is solid and honeycomb. In the first case we are talking about less durable material, which is used during the spring-summer season. For work in cold conditions and high humidity, solid polycarbonate is not suitable. Cell type is identified by characteristic stiffening ribs. If you make a cross section, the so-called honeycombs become visible. They give the material an increased level of strength.

Stiffeners allow installation at right angles to the surface or inclined. The noise and heat-insulating properties of cellular polycarbonate are explained by the presence inside of special cells in which air is accumulated. The second type of classification is based on the degree of durability of the coating. For example, “2Н” is a two-layer material, inside which there are honeycombs of rectangular shape. Its thickness ranges from 0.4 to 1 cm.

The number of layers is selected taking into account the climatic features of the region. “2H” is suitable for seasonal use in the European part of the country, and “5H” is suitable for year-round use in a more severe climate.

Advantages of cellular polycarbonate

The guaranteed life of the material - 20 years, subject to the rules of care. The second advantage is that cellular polycarbonate is 200 times stronger than silicate glass, being 6 times lighter. The list of advantages of the material continues the following facts:

- minimum level of load on the foundation;

- the level of light transmission ranges from 85 to 88%;

- polymeric material scatters sunlight;

- blocks dangerous UV radiation;

- good level of thermal insulation;

- increased level of material resistance to precipitation;

- operating temperature range: -40 ... + 120C.

Sheet characteristics are indicated on the packaging. If there are none, then they refuse to buy.

Material disadvantages

In addition to the positive sides, the coating has a number of "minuses". Opens a list of weak resistance to direct and strong mechanical stress. The list of shortcomings will continue the facts listed below:

- excessive transparency is typical of cheap materials;

- a significant amount of thermal gap - the more often temperature fluctuations occur, the more actively the material contracts and expands;

- excessive reflectivity.

The last "minus" is more noticeable in cases where the arched type of construction dominates in the greenhouse. Located inside the greenery will receive a minimum of sunlight.

Choose color and thickness

For the greenhouse or greenhouse suitable cellular or, as it is also called, cellular polycarbonate. Its thickness is selected taking into account the climatic characteristics of the region and the botanical features of the cultivated green spaces. Botanists recommend paying attention to a number of additional criteria:

- monthly precipitation;

- maximum wind speed;

- the type of paint used;

- crate step;

- greenhouse construction type.

For seasonal use during the spring and summer sheets suitable, the thickness of which is 3.5-4 mm. If the greenhouse works for 12 months, then it is better to purchase cellular polycarbonate, which is 7-8 mm thick. The color of cellular polycarbonate is selected taking into account the maximum t in the region. First place divides orange and red tint, which actively absorb dangerous UV. The second line is taken by a transparent type, which will provide natural lighting.

Practical advice on choosing

Polycarbonate sheets with different thicknesses are on sale. The larger it is, the greater the bending angle should be.

| Type of polycarbonate | Thickness (mm) | Recommended bending radius (mm) |

| Single chamber | 4 | 700 |

| 6 | 1000 | |

| 8 | 1400 | |

| 10 | 1750 | |

| Two-chamber | 16 | 2700 |

| Reinforced | 4 | 910 |

| 6 | 1400 | |

| Four-chamber | 25 | 4400 |

When choosing sheet thickness, emphasis is placed on the maximum amount of precipitation that falls in the region and the maximum wind speed.

Offers from various manufacturers

The store presents cheap and durable polycarbonate sheets. For the spring-summer use is suitable inexpensive option, and for permanent - thicker and more expensive. The minimum price is 2400 rubles, and the top bar is 10 thousand.

| Company | Description |

| Vizor | It's expensive. The material is quite demanding to care. |

| Plastilux | It will cost 1 sheet in the range of 4 - 5 thousand. Guaranteed service life is 10 years. |

| Italon | It is inexpensive. The coating is suitable for seasonal use. |

| "Actual" | For 1 sheet you need to pay up to 3,500 rubles. It will last 5-7 years. |

| "Polygale" | It is characterized by a high degree of rigidity. Guaranteed service life is 15 years. |

| Carboglass | It offers sheets, whose thickness is 6 m, and dimensions - 2.1 x 6 m. The coating is designed for use in temperate climates. |

You need to purchase material made in countries with more or less similar climate. Otherwise, the risk of losing the crop is great.

Some manufacturers offer polycarbonate labeled “light” on the market. Sheets are thinner and have no protective layer. From such a purchase should be abandoned, otherwise in 3-4 months you will need to do a repeated repair of the greenhouse or greenhouse.

How to determine the quality

Manufacturers in every way extol the goods, but the buyer should not lose vigilance. Before buying, pay attention to the characteristics of the surface. It should not be mechanical damage. The second caveat is that even in the presence of insignificant areas where the material is exfoliated, the purchase should be abandoned. The list of recommendations will continue the details listed below:

- ribbing ribs (not even position) is not permissible;

- You must refuse to purchase sheets without UV protection;

- if in the store they are displayed on the ribs, then the purchase should be abandoned.

The last point deserves special attention. Even the sheet, which initially had excellent characteristics, will become unusable if stored improperly.

Cutting rules

To work you need a construction knife. If it is not at hand, then take an electric jigsaw or a file with small teeth. If you have to work with thin sheets of polycarbonate, then they are placed on a sheet of thick cardboard. Up to a dozen sheets of polycarbonate are put on top of it for subsequent cutting. The procedure is as follows:

- remove foreign objects;

- carry out the layout of the sheet with a marker and ruler;

- put under both parts of the cut sheet of the board - 4x10x220 cm;

- use the "grinder" is allowed only in cases where the cut is performed on a flat line;

- for figured cut suitable stationery knife;

- if a sheet with a laminated surface is cut, then it is laid face up.

The final stage is blowing all the seams and honeycombs with compressed air.

We collect greenhouses from arcs

Greenhouses, collected from the arcs and canvases of covering material, are widespread in almost all…

Basic installation rules

During installation, you need to ensure that the stiffeners are located strictly vertically. Otherwise, condensation accumulates between the sheets. The second rule - the bend is performed strictly according to the radius recommended by the manufacturer. "Self-activity" will lead to a weakening of the bearing characteristics of the structure. Other rules for the operation of the material are as follows:

- prior to the installation of the panels, the ends are sealed - you will need a self-adhesive tape to work;

- direct installation is carried out using a polycarbonate profile;

- fixation is carried out using self-tapping screws equipped with thermal washers;

- as soon as installation is completed, remove the protective film.

Regular care - a pledge of durability of the material. Remove dust and other types of dirt only with a soft cloth. Use of a sponge is allowed. As the only possible cleaning agent use warm soapy water.

The use of cellular polycarbonate for the construction of greenhouses and greenhouses due to its durability. With a relatively low cost gardener receives protection from UV radiation and the vagaries of nature. Gardener takes into account the climatic features of the region. The more capricious the weather is, the thicker the leaf should be. Polycarbonate is unpretentious in care, so it does not take the trouble.