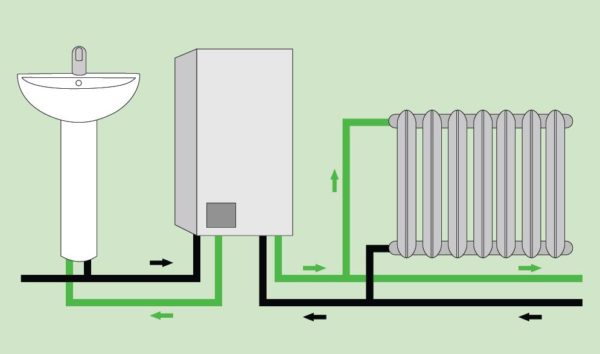

Double-circuit boilers are increasingly chosen as a more economical alternative to simple single-circuit systems. Heating the coolant and maintaining the required temperature level in the DHW system helps to save fuel, reduce maintenance costs and even control the operation of all equipment. But in order for such a boiler to serve for a long time and without failures, you need to correctly determine the type, find its high-quality performance.

Double-circuit boilers are increasingly chosen as a more economical alternative to simple single-circuit systems. Heating the coolant and maintaining the required temperature level in the DHW system helps to save fuel, reduce maintenance costs and even control the operation of all equipment. But in order for such a boiler to serve for a long time and without failures, you need to correctly determine the type, find its high-quality performance.

Device types

The most popular type of boilers with two circuits are gas. They are economical in terms of fuel consumption, reliable and have a high level of efficiency. Their installation is possible in houses of any type, they are compact and have an optimal price. A lot of information about such devices can be found on the largest construction portal remont-book.com. Those who plan to install will learn a lot. double-circuit heating boilers. Such systems can work on:

- liquid fuel;

- solid materials;

- electricity.

Liquid fuels are more efficient than solid fuels. It is easier to store and transport, while the heating equipment itself wears out less. Oil-fired units carry out heating due to a large built-in coil. This is the central element of such installations. An internal boiler is another characteristic of this type of double-circuit boilers. It does not take place, which is important.

Solid fuel double-circuit boilers are simpler in their design. They rarely have secondary sources of heating, the water for domestic hot water is heated with primary heat. Therefore, the price is significantly lower, from the point of view of repair they are easier. However, solid fuel is less environmentally friendly, the boiler will require regular maintenance, constant cleaning. It is difficult to achieve a constant heating temperature. Heavy solid fuel masses burn out gradually, so surges are inevitable. More modern double-circuit boilers with an integrated pellet system are deprived of this drawback. In them, the energy carrier loads automatically built-in mechanism, which simplifies operation for the owner.

An important characteristic of a double-circuit boiler is the type of heat exchanger. The stability of heating and the overall service life depend on it. In total, three types are divided:

- primary;

- bithermic;

- secondary.

Their combination determines effectiveness. The primary heat exchanger is very similar to a conventional radiator, which can be seen in an apartment or car. The design is the same: the central pipe and heat transfer elements to the carrier. Heating takes place directly due to the flame, which reduces the life of the system. However, each burned-out element can be replaced separately, which reduces repair and maintenance costs.

Their combination determines effectiveness. The primary heat exchanger is very similar to a conventional radiator, which can be seen in an apartment or car. The design is the same: the central pipe and heat transfer elements to the carrier. Heating takes place directly due to the flame, which reduces the life of the system. However, each burned-out element can be replaced separately, which reduces repair and maintenance costs.

Secondary elements are heated exclusively due to the coolant circulating in the system. There is no access to an open flame, so wear is slow. Hundreds of thin plates are installed inside the common case, which evenly distribute energy and are able to accumulate it, gradually giving back. Since there is no need to restrict the flow of hot water, owners can use several mixers at the same time without losing pressure and reducing the overall temperature.

How to choose the right

In addition to the design differences already described, dual-circuit systems differ in power, a set of additional options and the type of installation. All this must be taken into account when choosing a boiler, since it is no longer possible to compensate for the existing shortcomings. It is important to determine the power, as this is the main parameter. You can calculate the required indicator using a standard formula. It is necessary to calculate the total area of the heated rooms, then divide by 10. This will be the required amount of kW. It should be borne in mind that the calculation is correct for rooms with a ceiling height of three meters. In order for the equipment to cope with extreme loads, it could work under adverse conditions, it is necessary to add another 30 percent to the resulting number. In this case, it is possible to achieve a longer service life and ideal operation of the boiler without reaching its maximum capabilities.

In addition to the design differences already described, dual-circuit systems differ in power, a set of additional options and the type of installation. All this must be taken into account when choosing a boiler, since it is no longer possible to compensate for the existing shortcomings. It is important to determine the power, as this is the main parameter. You can calculate the required indicator using a standard formula. It is necessary to calculate the total area of the heated rooms, then divide by 10. This will be the required amount of kW. It should be borne in mind that the calculation is correct for rooms with a ceiling height of three meters. In order for the equipment to cope with extreme loads, it could work under adverse conditions, it is necessary to add another 30 percent to the resulting number. In this case, it is possible to achieve a longer service life and ideal operation of the boiler without reaching its maximum capabilities.

Since the double-circuit boiler must fulfill the option of supplying hot water, it is important to evaluate the parameter of the heating rate. It is expressed in liters and a range of degrees per minute. That is, the characteristic will indicate how many liters of liquid in one minute will be heated in standard mode by the specified number of degrees. For example, if at the entrance the readings are equal to plus 2 degrees, then at the outlet the boiler with parameter 11/35 will give 11 liters of liquid with a temperature of 37 degrees. The standard calculation assumes that this is enough for two consumers in a residential building.

The boiler can be wall or floor. The first option is more popular because it does not need a separate room, it is compact and at the same time productive. It is in this form that most of the dual-circuit type models are proposed. Floor devices are more powerful in terms of heating, more capacity in terms of one-time loading of any fuel. This is a good choice for a large residential building or a small utility room.

The boiler can be wall or floor. The first option is more popular because it does not need a separate room, it is compact and at the same time productive. It is in this form that most of the dual-circuit type models are proposed. Floor devices are more powerful in terms of heating, more capacity in terms of one-time loading of any fuel. This is a good choice for a large residential building or a small utility room.

The most important additional option is an autonomous security system. It guarantees that the equipment will stop its work in the absence of a coolant or liquid, as well as during sudden surges in pressure or temperature. The shutdown will occur when the draft is loosened or the burner is extinguished. A similar function is self-diagnosis. In addition to switching valves and relays, the system will be able to turn on the pumps, increase the power for a short time to prevent sticking after downtime or work at the minimum power level.

A useful feature will be self-regulation of flame power depending on climate change or on a schedule. This allows you to spend a minimum of time on manual tuning and at the same time save fuel. However, for many buyers, the key parameter is the price of the equipment. Top models with an expanded list of functions cost from 60 to 80 thousand rubles. These are the most powerful versions, often of the floor type, requiring additional connection to the mains. Budget gas can be purchased at a price of 30 thousand rubles.The simplest models of solid fuels that do not have a secondary radiator are on sale at a price of 15 thousand rubles. However, they require manual adjustment, regular diagnosis, but at the same time they have low power.

A useful feature will be self-regulation of flame power depending on climate change or on a schedule. This allows you to spend a minimum of time on manual tuning and at the same time save fuel. However, for many buyers, the key parameter is the price of the equipment. Top models with an expanded list of functions cost from 60 to 80 thousand rubles. These are the most powerful versions, often of the floor type, requiring additional connection to the mains. Budget gas can be purchased at a price of 30 thousand rubles.The simplest models of solid fuels that do not have a secondary radiator are on sale at a price of 15 thousand rubles. However, they require manual adjustment, regular diagnosis, but at the same time they have low power.

When choosing a double-circuit boiler, it is necessary to evaluate all the parameters. The heating power, the ability to control temperature, the level of safety are important. By choosing an expensive model with bithermic heaters, you can achieve the greatest comfort, however, models with primary elements will last a long time with the right service. Double-circuit boilers are a good solution in terms of saving space and money. They are suitable for owners of small apartments, residents of country houses.

How to decorate and highlight garden paths in an original way?

How to decorate and highlight garden paths in an original way? How to grow Kombucha "from scratch"?

How to grow Kombucha "from scratch"? 8 practical ideas for using linoleum in the garden

8 practical ideas for using linoleum in the garden Useful crafts from do-it-yourself canisters for the garden

Useful crafts from do-it-yourself canisters for the garden