A mechanical assistant to farmers, who is paired with a wheeled tractor riding in the fields, scatters organic fertilizers. All organic matter is evenly distributed throughout the field. The spreader of organic fertilizers copes with a large number of peat, compost fertilizers, mass of sludge, bird droppings.Fertilizing machines - a modern need for industrial agricultural technologies. Mechanically, they introduce fertilizers into the ground in dried or granular form. The spreading method is designed for uniform application of dry fertilizers. The industry produces a large selection of organic fertilizer spreaders. They are able to evenly feed top dressing on arable land for future arable land, so that the land is saturated with nutrients, rests during the winter, and in spring it would be possible to confidently sow and plant crops for a new crop.

Content

Organic fertilizer spreader: how to apply solid and liquid fertilizers

Russian companies are confidently leading the world in the production of organic fertilizer spreaders. Domestic equipment in many ways surpasses the complexes supplied from China and Poland - the chassis-body. The principle of operation of domestic units for introducing mixtures of organics allows us to distinguish two types - spreaders trailed and mounted. Manufacturers offer a large selection of units for the competent use of top dressing in the fields. Each model of the unit has its own principles of action, they are intended to perform a different job, depending on the density characteristics of the applied top dressing.

Description of organic manure spreader

Trailer units are popular with farmers working on large areas of land. They refuel several trailers at the same time, leave them at the edge of the field. The tractor driver, the driver, spreads fertilizers from one trailer, then puts them empty on the edge of the field, hooks the loaded one, and so continues the work without wasting time on loading. Mounted units are designed for the complex supply of various top dressings, including liquid, with predetermined proportions. They are used for cultivating small sown areas.

Organic Fertilizer Spreader

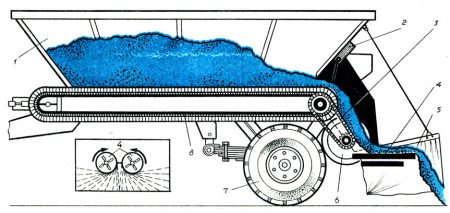

The structural basis is a chassis frame made of durable high alloy steel and steel alloys. The frame is equipped with a trailer attachment for the tow tractor. The frame carries a body structure; its equipment necessarily includes a scraper conveyor that moves the fertilizer mass to the spreader. The conveyor also speeds up unloading when the trailer is used as a trolley to transport various bulk cargoes.

The conveyor conveyor includes 4 chains with scrapers with clamp fastening in the design 4. All chain lines are tensioned and bolted. Functions to the conveyor are provided by a tractor shaft for power take-off. The fertilizing mass from the conveyor rolls is first sent to the chopping drum, then to the spreading drum.

The chassis consists of two pairs of wheels equipped with a system of balancers and supports. The brakes of the trolley are connected to the tractor brakes by means of an adapter; the system is triggered by pressing the pedal by the driver in the tractor cabin.

ROW-6

The organic fertilizer spreader ROU-6 produces the old enterprise BelotserkovSelMash, in the arsenal of which there are many agricultural machines for various purposes. The unit is a four-wheeled chassis of a trailed type with a body, in which a spreading mechanism is mounted, connected to the power take-off shaft on the tractor. If the spreader is removed, then there remains simply a convenient trolley to any tractor.

Machine purpose

The modern design of the unit for spreading fertilizers on an industrial scale makes the ROU-6 machine convenient and widely popular. Its main purpose is to accurately disperse fertilizers. These machines have been used for a long time, and even on turns at the edge of the field, the tractor evenly distributes fertilizers.

Using the ROU-6 machine optimizes agricultural production, increases yields, and allows you to fertilize the soil with various top dressings. The spreader accurately doses the fertilizer application and evenly distributes it throughout the field.

Advantages and disadvantages

Tractor equipment significantly reduces the cost of purchasing mineral fertilizers, because they are scattered across the field in the exact dosage on the recommendation of the Instructions for the use of fertilizers. It is recommended to spread organic fertilizers such as manure compost throughout the field, late processing is allowed.

The main advantages of cars:

- convenient fertilizer feeder;

- automatic dosage control of feeding is provided;

- spreading is carried out with high quality, practically at no cost;

- units are easy to manage;

- units are easy to use;

- it is possible to use the chassis as a regular transport trolley.

Advantages of ROU-6:

- adjustable transport speed;

- mechanized fertilization in the soil;

- fertilizer spreading width - up to 8 m;

- the spreading device has the principle of continuous feeding;

- fertilizers are scattered efficiently and evenly;

- rolled wheel tractors due to this less compact the earth.

When fertilizer is not required to be scattered, the scattering unit is removed from the body and the trolley is used as a roomy body for transporting goods. A conveyor remains mounted on the trolley, which quickly and conveniently unloads the body. The cart is convenient and practical, allows you to store or transport goods without problems. Vehicle maintenance costs are paid for by the profit from the crop.

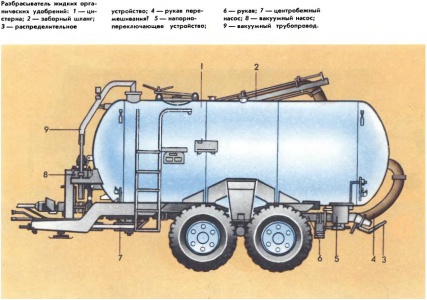

MZHT-F-11

The unit for liquid organic fertilizers MZhT-F-11 is produced by the BobruiskAgroMash production association. It is a powerful transport chassis on two pairs of wheels with a towing device for attaching to traction transport. A capacious tank with a capacity of about 11 tons of liquid with a centrifugal pump and a filling device is installed on the chassis.

Machine purpose

The liquid fertilizer tank is designed to load itself, mix components during transportation if combined mixtures are introduced. When liquid organic fertilizer is distributed on the surface of the field, the filling device provides a continuous surface coating with a liquid solution.Self-loading is provided by equipment with a vacuum system and a sunroof, allowing you to load the machine offline.

The operation of the trailer tank from the cab of the traction transport is controlled, since the connection of the brake, electrical systems is ensured. The machine MZhT-F-11 is successfully used in the transportation of industrial water, in long-range irrigation of fields, for washing equipment, washing and watering roads.

Special use! The possibility of using a tank with a filling system and a centrifugal pump to extinguish fires, including forest fires, is especially noted, since the wheeled tractor is maneuverable and can drive up to inaccessible places.

Advantages and disadvantages

The equipment of MZHT-F-11 with a filling device is superior in method and spraying to top-feed a machine of a similar class. The quality and uniformity of the distribution of fertilizers over the entire area increases, and the emission of nitrogen-containing compounds into the air decreases to a minimum. Using the unit allows you to increase the productivity of fertilizer by 20%, while reducing the contribution of labor to pollination by 15-20%.

The unit MZhT-F-11 is equipped with a vacuum self-loading system, the self-loading time is from 4 to 7 minutes. Fast self-loading is important when using the machine to extinguish forest fires. The length of the hose allows you to pick up fluid in reservoirs at a depth of 2.5 m. The tractor control unit has a spray dispenser that allows you to adjust the fertilizer application, depending on the field preparation plan, from 10 to 60 t / ha.

Bobruisk AgroMash produces tanks with different tank capacities - from 4 with an increase of 23 m3. Their design does not fundamentally differ, it is a trailed or semi-trailer chassis for horizontal placement of a tank of cylindrical shape with rounding on both sides. The tank is equipped with a vacuum pump for refueling, internal devices for mixing different components of the mixture and creating the pressure necessary for the work. There is in the design and dispenser for spraying fertilizing.

How to apply solid and liquid fertilizers

Solid and liquid fertilizers are introduced by machines of various types. For solid units, ROU-6, PRT-7, and others are provided. Liquid fertilizers are sprayed by machines such as MZHT-F-11 and its modifications.

MZhT-F-11 machines evenly distribute liquid organic fertilizers along the field surface by adjusting the change in the angle of inclination of the reflective shield, which the filling device is equipped with. In the same way, the width of the field is also regulated when spraying liquid. Unloading organic fertilizers in liquid physical form is carried out using a centrifugal pump. At the end of work, the tractor delivers the unit for self-loading, which is provided by the vacuum installation.

Machines of the type ROU-6 distribute organic fertilizers in solid physical form over the fields. The dose of fertilizer application depends on the speed of the complex and the activity of the conveyor arranged in the body. At the same time, the speed of movement does not affect the uniform distribution of fertilizers across the field, this is due to diffusers with centrifugal working bodies.

Reviews

Summer residents have long been convinced of the benefits of organic fertilizers, they themselves create compost pits, prepare solid fertilizers for feeding their plots. Hand tools are a thing of the past, mini-equipment appears in vegetable gardens and household plots.

Ivan, Kursk:

“All his life he worked in the field on various agricultural machines, and to his retirement he acquired a mini-tractor for his own garden. We have a large family, we keep several gardens, so the tractor was just a great helper. Both plows and harrows got to him, everything, as it should be.But I was thinking about fertilizing, and I realized that without a compact small device we just can not do. In addition, I want one unit to be able to make both liquid and solid fertilizers. I considered various options, and settled on the Gardena Comfort 800 model. I got, as they say now, 3 in one: this unit also disperses the seeds on the lawns. In general, I am satisfied with the purchase. As an experienced machine operator, I like this technique. ”

Ilya, agronomist of the "Oriole" concern:

“Manufacturers of agricultural machinery will always receive demand for products, because they do not stand still, constantly improve models, develop modifications through the introduction of technical innovations. The improved model of the fertilizer spreader ROU-6 allows agronomists to work with ready-made granular and powdered fertilizers, and with such masses as peat, sapropel. With one unit, we got the opportunity to diversify the application of fertilizing, increase crop yields. ”

Cover material for plant care: features of use

Cover material for plant care: features of use Types of winter covering material for plants

Types of winter covering material for plants Biohumus Farm

Biohumus Farm What covering material to choose for a greenhouse?

What covering material to choose for a greenhouse?