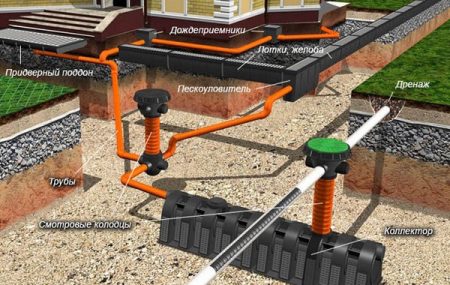

The storm water inlet is a structural element of the storm drainage system necessary to protect the foundation of buildings, pavement and basement from the penetration of rainwater.

The storm water inlet is a structural element of the storm drainage system necessary to protect the foundation of buildings, pavement and basement from the penetration of rainwater.

The water which has got into the receiver then goes to the collector. The element is simple to install, there is no difficulty with its operation and replacement. The selection of a suitable storm water inlet is carried out taking into account the type of storm sewer, terrain, soil and climate.

Content

What is a storm water inlet and what is it for

The storm water inlet directing the fluid into the sewage system may be round or square in shape. It is installed in order to collect and clean up the accumulated liquid, sending water to the external storm sewer system. The element is designed to protect building structures from the damaging effects of high humidity. In urban environments, it is used to collect water from the road surface.

It is used not only in private housing construction, but also in the construction of industrial facilities. In the first case, the choice between cubic receivers and options with a vertical outlet is presented. A feature of the cubic is the local collection of liquid with subsequent dispatch to the storm sewer.

The scheme of this model provides:

- grating;

- partitions;

- cart.

Vertical drain solutions collect fluid from pipes and gutters. The design of the inner surface eliminates stagnation of accumulating water. Receivers of this type do not provide a lattice, which allows water to flow through the structure without interference. When looking at solutions with a vertical outlet, you can find baskets and partitions.

The option for large enterprises is carried out in the form of a chamber with a grill made of cast iron. The chamber is represented by concrete rings or is made of plastic.

What can you make storm water inlets for storm sewers

When choosing a storm water inlet, priority is given to the material of its manufacture. Available solutions from:

- plastic;

- cast iron;

- polymer composites;

- concrete.

Each of the options has its pros and cons, dictated by physical and mechanical properties. The final decision is made taking into account the type of facility for which a storm sewer system is being developed.

Features of storm water inlets for storm sewers

The main purpose of cast-iron solutions is to remove water from the roadway. The mass of storm water inlets can vary from 80 to 115 kg - it all depends on the shape and size. Elements are appreciated due to their long service life and excellent throughput, which is extremely important for the operation of industries and urban infrastructure.

It is allowed to use in the field of residential development for projects requiring the removal of a significant amount of water on a regular basis. Installation of cast-iron models is impossible without the use of special equipment. The manufacturing process involves coating to protect against corrosion.

Concrete storm water inlets are characterized by maximum strength. In the manufacture of elements, it is possible to introduce steel fibers for the purpose of micro-reinforcement. Perhaps the creation of storm water inlets of a cubic or cylindrical shape.In the first case, a plastic branch is installed, which allows to reduce the total weight of the structure. If it is necessary to create a particularly durable raincoat, use heavy concrete with the introduction of steel fiber. The optimal shape in this case is cylindrical.

Most often, concrete products are used in the construction of large roads and highways, at facilities that are subject to increased construction requirements for strength and reliability during operation.

For private housing construction, this option is not suitable due to the difficult installation and margin of safety, which will not be used in practice. Before installing the structure, you need to create a sand or gravel pillow.

Now the most popular solution is a plastic storm water inlet. With the help of modern technologies, an optimal plastic structure has been obtained, preserving a single structure even with severe external pressure due to stiffeners. Available solutions not only for country estates, but also for parking large vehicles that can withstand up to 90 tons of load.

A cubic shaped plastic storm water inlet can drain accumulated liquid to either side. The demand for polypropylene models is explained by the ease and elementary installation, which does not require special equipment. The design is cleaned of debris without unnecessary problems. The maximum size of a standard product is 500x500x500. In the manufacture of gratings, plastic with chemical additives or cast iron is used for cases requiring resistance to a large load.

The optimal solution, which has not yet gained sufficient popularity, can be called storm water inlets obtained from polymer composites. They combine the best properties of other options: simple installation and elementary operation of plastic products, strength and corrosion protection of concrete solutions. A separate item means high bandwidth. At the moment, polymer composite products are more expensive than others, therefore, in order to save money, when developing a project, concrete or polypropylene ones are most often used.

Design features of storm water inlets

In practice, storm water inlets with one chamber and a rectangular-shaped grill installed at the top are best recommended. The grate is selected based on the need to ensure high water throughput, eliminating the penetration of foreign objects. It is possible to increase the overall strength due to the installation of stiffeners working to resist external loads. If necessary, the structure is reinforced with metal strips or fasteners during insertion into the system.

The use of cast-iron and concrete storm water inlets in the construction of the roadway does not affect the structure and integrity. To solve the problem, sewage receivers are installed in the form of borders. There are products with a hatch that extends the functionality.

The grate is installed in order to filter fragments and larger debris, to protect people from accidental injuries. Some models have a filter that blocks the ingress of sand and other small debris, simplifying operation several times.

How to choose the right storm water inlet

When choosing a suitable storm water inlet, it is necessary to take into account not only the design of storm sewers. The features of the climate, the total annual rainfall and the rate of precipitation for each month, and the physical and mechanical characteristics of the soil are taken into account. All data for the design are set out in the regulatory building documentation.In order for the receiver to cope with the volume of water, it is necessary to take into account the total area of the territory for which a liquid disposal system is being developed. The design process takes into account the terrain and external factors that may affect the durability of the product.

The most common solution for suburban areas is a small plastic stormwater inlet equipped with a basket, partitions and grille with stiffeners.

If the estate area exceeds standard values, you can use a cast-iron receiver with corrosion protection, which is characterized by high throughput. Engineers do not recommend installing concrete products in standard conditions.

How to choose a storm water inlet according to the load class

There is a classification according to the load class, which helps to choose a suitable storm water inlet for certain operation tasks:

- Class A 15 (15 / 1.5) is considered the minimum load solution. Such products are used in the design of parks and pedestrian zones. A15 is suitable for the vast majority of country houses and summer cottages.

- Class B 125 (125 / 12.5) is able to withstand the load exerted by several cars. Intended use - garages on the territory of private real estate.

- Class C 250 (250/25) is installed in spacious parking lots of vehicles on the territory of motorways. Most often used by engineers in the construction of the roadway.

- Class D 400 (400/40) is suitable for large gas stations in industrial facilities. Storm water inlets cope with the drainage of water that accumulates in factories.

- Class E 600 (600/60) for objects subjected to high loads. The design is used at berths, especially large industrial enterprises.

- Class F 900 (900/90) is as strong as possible. Designed for airports and military facilities.

If we take into account where the structure will be operated, then the probability of overpayment for an unused margin of safety is excluded.

Carrying out installation work of the storm water inlet

Storm water inlets are installed in places where liquid most often accumulates after precipitation. In the process of installation, specialists select the optimal location in order to ensure the operation of the structure without loss of water discharge.

At the first stage, you need to dig a pit taking into account the size of the storm water inlet and provide a reserve in case of soil deformations (up to 40 cm). A width margin is provided for the penetration of concrete mortar (3 cm). Further, the workers create a sand or gravel pillow of small thickness. In order to seal it, you need to add water, and then tamp the sand manually.

Before connecting the storm water inlet to the pipes, you need to make sure that the installed system is correct, that all design heights are observed when installing the input and output lines. The process itself is carried out in a few minutes. Then the bottom of the pit is poured with concrete mortar for reliable fixation of the element. It is important to ensure a stable position of the receiver in a place designated by the project. The solution is also added from the sides. In the case of plastic products, it is recommended to install a grille to protect against possible deformations. Installation work is completed after the installation of the basket and partitions.

Storm water inlets lose operational properties in case of errors with concrete pouring during installation. Premature coating of the site also affects efficiency.

Reviews of specialists

Specialists in the construction industry note a wide variety of wastewater receivers, their simple installation and the ability to maintain their original reliability for several decades.

Leonid: It is best to select storm water inlets with gratings of a fine-meshed structure - these greatly simplify operation.Almost all the models we install are made of plastic or concrete, many refuse cast iron, considering it obsolete.

Dmitry: All the work of storm sewers can be disrupted due to an error when choosing a place for the storm water inlet. When installing, we focus on the depth of freezing of the soil and the general features of the relief of the site. Plastic models without stiffeners are suitable for standard tasks.

Ivan: Errors in the installation or selection of the receiver will be clearly noticeable in spring and autumn. If the operation of storm sewers is seriously hampered by the storm water inlet, it is best to replace the part as soon as possible, eliminating the risk of washing out and destroying the foundation structure.

Storm water inlets effectively cope with the task of removing accumulated moisture. Before choosing a product, you need to take into account the topography of the territory, the intended purpose of the object, climatic conditions and soil features. For the first case of installing the receiver, it is better to hire specialists in engineering systems.

Why is a greenhouse open top?

Why is a greenhouse open top? Greenhouse "Butterfly", is it worth it?

Greenhouse "Butterfly", is it worth it? Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning

Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning Shed greenhouse, pros and cons

Shed greenhouse, pros and cons