An opaque enclosure around the land is an easy way to protect your privacy from prying eyes or prying eyes. If you choose the right material, then to install a fence with your own hands you will need simple skills with a moderate budget. You can even fix sheets of colored corrugated board to the frame from the profile pipe alone.

Content

Material benefits

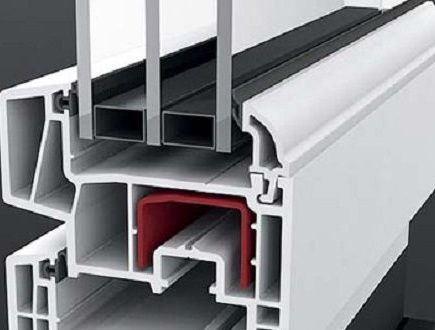

Profiled steel sheet is a strong, durable, relatively lightweight material. Galvanized steel, coated with several layers of polymers, is reliably protected from corrosion and mechanical damage. The external color coating with a glossy or matte surface can be plain or imitate natural materials. The bends of the sheet profile make the surface more decorative, serve as stiffening ribs, without burdening the structure.

Profiled steel sheet is a strong, durable, relatively lightweight material. Galvanized steel, coated with several layers of polymers, is reliably protected from corrosion and mechanical damage. The external color coating with a glossy or matte surface can be plain or imitate natural materials. The bends of the sheet profile make the surface more decorative, serve as stiffening ribs, without burdening the structure.

The frame from the profile pipe is not subject to destruction from weather conditions - exposure to moisture, temperature changes. It is easy to design and then mount. To connect the vertical supports with the transverse logs, it is enough initial skills in working with welding. If welding is not possible, a bolted connection may be used.

Project development

To carry out the calculation of the amount of material for the future fence, you can use one of the finished projects published on the Internet, or you can develop the project yourself. The following points should be considered:

To carry out the calculation of the amount of material for the future fence, you can use one of the finished projects published on the Internet, or you can develop the project yourself. The following points should be considered:

- the thinner the profiled sheet, the more support you need;

- a professional sheet with a smaller depth of wave is easier to mount;

- too high a fence will require additional supports and fixtures due to wind load:

- during installation, the sheets should be superimposed with approaching one wave:

- metal rolling for gates and gates it is better to calculate separately.

Usually the distance between the pillars is 2-3 meters. For poles, it is better to take a square pipe with a wall thickness of at least 3 mm and a cross section of 50-60 mm. For the gate and gate, a pipe with a cross section of 80 mm is required. For cross logs more suitable profile pipes with a rectangular section of 50x25, 40x20 or 30x20 mm.

Frame installation

The appearance and stability of the fence depends on the proper installation of the supports. They should be strictly vertical - a plumb line should be used to check the vertical. To prevent corrosion damage, the metal should be insulated from contact with the soil. To do this, a sand and gravel cushion is poured onto the bottom of the recess intended for installation, and the surrounding space after fixing the profile pipe is filled with a mixture of concrete with crushed stone.

The appearance and stability of the fence depends on the proper installation of the supports. They should be strictly vertical - a plumb line should be used to check the vertical. To prevent corrosion damage, the metal should be insulated from contact with the soil. To do this, a sand and gravel cushion is poured onto the bottom of the recess intended for installation, and the surrounding space after fixing the profile pipe is filled with a mixture of concrete with crushed stone.

Horizontal logs are welded to the posts on the sides or fastened end-to-end from the outside - with a welding joint or bolts.With a bolted connection, the logs rest on the holder - a ready-made bracket or a small piece of a corner of a suitable size.

After assembly, the frame must be cleaned from scale and painted to protect it from corrosion. If the frame is assembled without welding, then the joints should be especially carefully coated. To mark and align the horizontal jumpers, pull the thread and check its level.

Installation of a professional sheet

To pin corrugated board to a metal frame, self-tapping screws with washers or rivets, which are placed on the concave parts of the sheet for the most snug fit, are best suited. In order for the mount to come out strong and rigid, you should not make it too rare - it is better through one or two waves of the profile of the profiled sheet. If the fence is high - 2 meters and above - then fasten should be placed on two logs in a checkerboard pattern, alternating waves of relief.

The most critical step in the installation of corrugated board is the installation of the first sheet. It should be fixed strictly vertically, the position of all other sheets depends on this. Each next sheet of the first wave of relief is superimposed on the previous one, while the location of the joints does not necessarily coincide with the pillars.

The gate and gate are made separately - first, the frame is welded according to the drawing, hinges and profiled sheets are attached to it. All wings should be checked for rectangularity by measuring the diagonals, which should be the same inside each frame and in symmetrical parts. It is also better to use a welded joint to fasten the hinges to the support posts.

Decking and profile pipe are not the cheapest materials for making fences and do-it-yourself fences. However, durability, aesthetics and a long service life - up to several decades - makes them more profitable in comparison with more budget materials. All stages of design and installation are within the power of a person with minimal engineering skills.

Why is a greenhouse open top?

Why is a greenhouse open top? Greenhouse "Butterfly", is it worth it?

Greenhouse "Butterfly", is it worth it? Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning

Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning Shed greenhouse, pros and cons

Shed greenhouse, pros and cons