To get an early harvest, and then throughout the entire garden season to enjoy ripe and tasty vegetables, regardless of the weather, many summer residents build greenhouses in their area. At making greenhouses Before, polyethylene film was widely used, but today it has been successfully replaced by a material such as polycarbonate.

To get an early harvest, and then throughout the entire garden season to enjoy ripe and tasty vegetables, regardless of the weather, many summer residents build greenhouses in their area. At making greenhouses Before, polyethylene film was widely used, but today it has been successfully replaced by a material such as polycarbonate.

How to make a polycarbonate greenhouse with your own hands from a profile, drawings and other features of the construction of such an important, but not very difficult structure, we will consider in this material. How is polycarbonate good when compared to film? It is durable, it does not need to be changed every year. Once constructed, with the right approach and care, it can be operated without problems for many years.

On the video instructions for this material, you can see in detail the drawings and other points on how to create a polycarbonate greenhouse with your own hands from the profile. But further in the text, we will consider the main important points, which are often not covered in video stories, but that have important theoretical and practical significance.

Content

About cellular polycarbonate

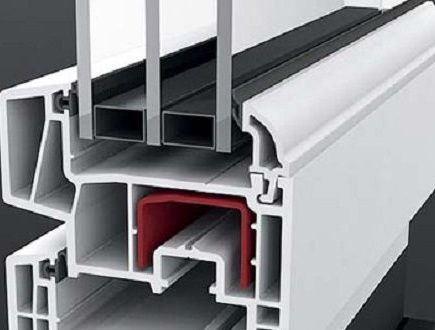

This versatile greenhouse material is a two-layer plastic sheet of different thicknesses. For greenhouses, sheets are taken with a thickness of five millimeters, and in size 6 * 2.1 meters. If desired, they can be easily cut to the desired size.

The advantages of polycarbonate for greenhouses compared to film or glass:

- High impact strength. Even when compared with glass, the strength of polycarbonate is two hundred times more not to mention the film.

- Complete protection of plants from exposure to ultraviolet rays.

- Temperature changes tolerates well. Here we can talk about a range from minus forty degrees of cold to plus sixty degrees of heat.

- The natural diffusion of sunlight through the material due to this plant does not tend to receive sunburn, already inside the greenhouse.

- Plastic, as already noted at the beginning, has two layers. This means that the greenhouse will be well insulated in terms of thermal conductivity.

- Building polycarbonate greenhouses, and then looking after them is simple and easy. Self-tapping screws are suitable as fasteners for the design.

- By weight, polycarbonate is less than glass. Transportation, installation and construction of the greenhouse will be simple and quick.

- Dust does not accumulate on the material in question. Some contaminants can be easily and quickly removed simply with water.

- It does not burn, if there is an effect of fire, then polycarbonate will melt, but not flash.

- The cost of the final design can be compared with the glass version, but the advantages of the greenhouse will be much greater, and installation is much easier.

How to care for polycarbonate

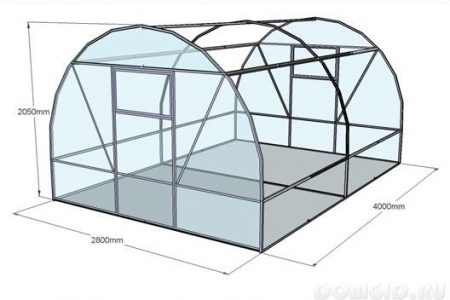

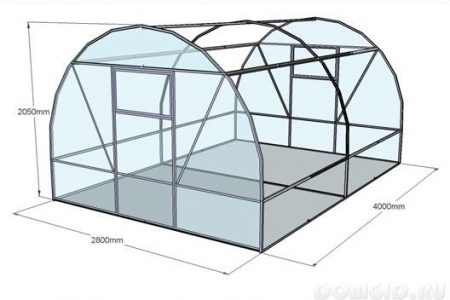

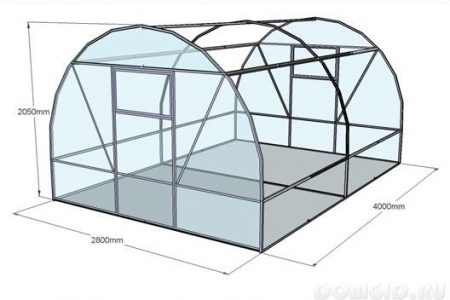

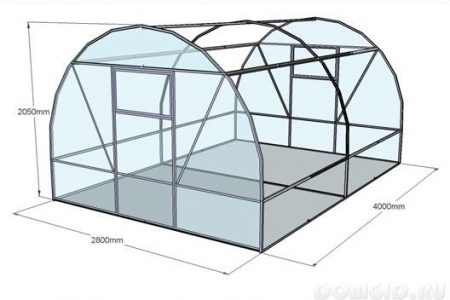

In the photos and drawings shown in this material, you can see how a greenhouse is made of polycarbonate with your own hands from a profile. In order for the construction to serve faithfully for a long time, it is necessary to follow some requirements for the care of the material. Do not use abrasive pastes, chlorine or alkalis to clean the surface: just clean water is enough, you can dissolve a little laundry soap there. how care for tomatoes in a polycarbonate greenhouse.

So that mold and strokes do not form on the surface of the polycarbonate, it is important to monitor the end part: moisture or insects should not get on it. In winter, try to avoid the formation of ice, because, it can lead to deformation of the structure.

Important about the arrangement of the greenhouse

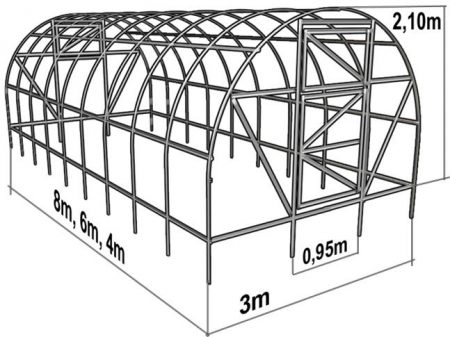

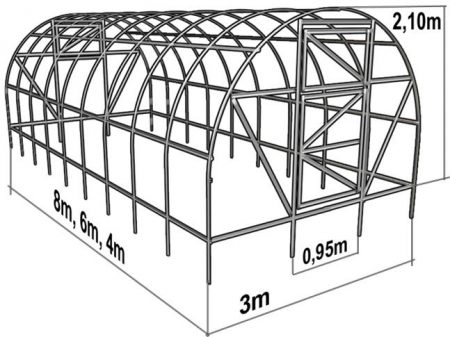

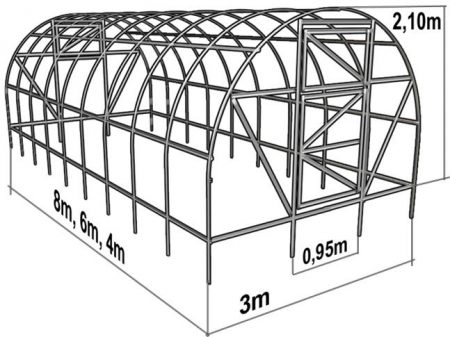

Do-it-yourself polycarbonate greenhouse from a profile, drawings and assembly order are considered further. First of all, you need to perform a specific drawing in order to immediately understand exactly where the structure will be made on the site. Under the greenhouse, a lot of free space is required, so there should not be trees or any additional structures nearby. Ensure good ventilation, sufficient light and heat.

Variants of the shape of the greenhouse depending on the specific conditions and the selected drawing:

- To save materials, but along the way it will help to save heat, you can make a greenhouse next to the wall of a building. That is, to bind the structure to the existing construction on the site.

- The shape of the roof of the greenhouse can be single-pitched or gable.

- The arched roof is quite common. But from polycarbonate to make it quite difficult. Here you need a special pipe bender or you can buy ready-made arched structures, but their cost is quite high.

- It is very important for a greenhouse of this type to choose and equip the foundation. Because, from this initial stage will depend on the strength of the future design, its practicality and durability.

Construction technologists

To create polycarbonate greenhouses with your own hands, use a wooden or plastic, as well as a metal frame. It is extremely important to immediately provide openings for ventilating the greenhouse: these are windows and doors.

If the roof is made in the form of an arch, this additionally helps to increase the volume of air inside the structure, which positively affects the growth and development of the crop. The built-in leverage is an additional complication, but it will allow you to open the vents built into the roof, which is extremely convenient during operation. As for the size of such a window, they should be at least one fourth of the surface of the entire roof. Doors are additionally made not only at the end, but also in the side parts of the structure for future good air circulation.

Square pipes, as well as metal corners, are perfectly suitable for the frame. First make a harness, and then attach it to the finished foundation. Paint the metal structure before installing it. how get rid of a spider mite in a greenhouse.

Why is a greenhouse open top?

Why is a greenhouse open top? Greenhouse "Butterfly", is it worth it?

Greenhouse "Butterfly", is it worth it? Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning

Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning Shed greenhouse, pros and cons

Shed greenhouse, pros and cons