A polycarbonate greenhouse and do-it-yourself PVC work are built quite simply and quickly. But for this process, by itself, it is required to prepare correctly and in advance. With their own hands it is easy and cheap to make greenhouses from plastic pipes, it is these two factors that primarily attract gardeners. But, it is also worth noting the good workability, elasticity of this material.

A polycarbonate greenhouse and do-it-yourself PVC work are built quite simply and quickly. But for this process, by itself, it is required to prepare correctly and in advance. With their own hands it is easy and cheap to make greenhouses from plastic pipes, it is these two factors that primarily attract gardeners. But, it is also worth noting the good workability, elasticity of this material.

Content

Required Items

You can build a greenhouse out of PVC pipes with your own hands quickly enough. At the same time, this can be done with a minimum set of tools. Such a greenhouse will last for a long time from polycarbonate, but in principle, even a film can be used as a material for maintaining heat.

Important! A do-it-yourself greenhouse made of plastic pipes is small in size, this can be seen in the video. Such a greenhouse should be made if it is not planned to grow the crop year-round, but for seedlings this type of greenhouse made of PVC pipes with its own hands perfectly fits. Master class as yourself lay the stove in the country.

As part of the design, there is always a foundation (how to make it can be seen separately in the video), frame and coating (in this case, it must be made of polycarbonate).

Material as shape definition

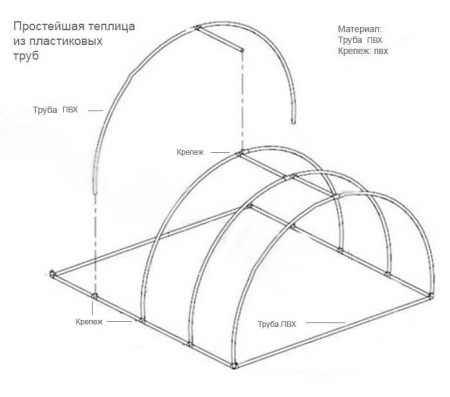

In order to make a greenhouse in your area at minimal cost, PVC pipes are ideal for the frame. But even with such a simple greenhouse, the options for attaching pipes to the frame can be different. Before starting work, one condition must be observed: the greenhouse will be arched in shape.

1. If you take a piece of a 1000 mm PVC pipe and lay it on two supports, and leave the pipe in the middle free and push on it, it will sag. It is clear that for the construction this is a big minus.

2. PVC greenhouse with straight walls requires the installation of additional stiffeners and stops so that the pipe does not sag in the center. But in this material it was already noted that such a greenhouse with its own hands will be small in size and additional supports are extremely undesirable.

3. If, however, the tube is bent into an arc and secured in this position, then when pressed on the central part, it will be elastic. Arrangement polycarbonate greenhouses: features and tips.

Without a foundation?

Some videos show that you can build a PVC greenhouse without additional foundation organization. This will save money, and effort, and even time. If the greenhouse is built without the need to be used all year round, then the foundation can be abandoned.

But, of course, for the strength and durability of the structure, it is best to do it precisely from the foundations. The standard width of a polycarbonate sheet is 2100 * 6000 mm, depending on this, calculations are carried out for a specific greenhouse.

How to determine the size

An arched greenhouse is made of bent plastic pipes, when they get this shape, they become a regular arc. With a sheet width of 3821, half the circle will be a radius of 1910 mm, that is, this is the full height of the greenhouse and half its width. It turns out, reducing the width of the greenhouse, respectively, will decrease in height.

The carcass will be 900 mm in length, that is, if there are eight sections, you get seven spans, it turns out that the sheet will be 6300 mm in total.Other sizes can also be taken, it is important to understand the principle of calculations, it can additionally be seen on the video.

Foundation building

There is no exact scheme for each specific case how a greenhouse is made of plastic pipes with its own hands. However, the frame of the future greenhouse for specific sizes can be assembled from boards. Prior to installation, it is recommended to impregnate the tree with a special solution that will protect the material for a certain time from moisture and mold. Put the frame on the prepared flat area. Now you need to check that the rules of the diagonal of the frame are respected.

To do this, you will need to make four pieces of reinforcement from the reinforcement 500 mm in length and drive into the corners of the frame on the inside. Carefully measure the diagonal, and then hammer in the fittings. What kind do it yourself do-it-yourself crafts.

Arcing

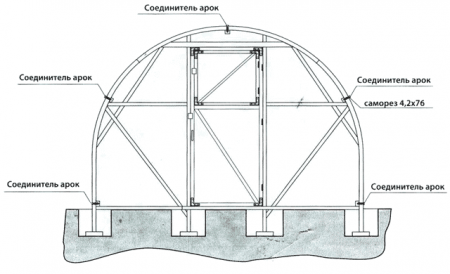

The next step in the construction of a greenhouse made of polycarbonate and PVC pipes with your own hands is to properly make and install arcs from plastic pipes. From the reinforcement, you need to cut 14 pieces of 70 mm in length, watch the video on how this is done. Next, draw a marker on the frame from the inside. The first mark is made at the very edge, and all the rest are 900 mm apart.

Now, according to the marks on the outside of the frame, drive in segments of the reinforcement, only 300 mm should remain sticking out. Mark the width, to do this, divide the width in half and pull back 400 mm in general, making marks. Further, arcs are made from PVC pipes. It is necessary to take two segments of 3000 mm, weld together, so that there is a cross in the center.

As for the manufacture of external elements of arcs, they are made differently. Pipes need to be connected in the center with straight tees, the arcs are now ready for installation. We remind you that polycarbonate sheets will be used for the greenhouse from above, how to fix them exactly can be seen in the video for this article.

Advice! Paste pieces of plastic pipes into the fittings with your own hands, you need to length along one side, then bend and insert the other end to the other side. That is, over the already made wooden frame (see video) there will be PVC pipes, which will become the arches for the future do-it-yourself polycarbonate greenhouse.

Polycarbonate coating

In addition to plastic pipes and a wooden frame, polycarbonate sheets are required for this greenhouse. They will wall the walls and the roof, so that in the end a place will be obtained where the plants will always be warm and light. With the sides, everything is quite easy - you need to insert wooden blocks between the ribs and you get a flat surface with seals. A polycarbonate sheet is easy to mount - you will need to use self-tapping screws to fasten it.

As for how a polycarbonate sheet is attached to an arched structure made of PVC plastic pipes, in all details this process can be seen in the video and then everything will only be repeated with your own hands.

To increase the life of the polycarbonate greenhouse and plastic pipes, it is recommended to make a concrete foundation in advance. The design itself and its installation will not change from this, but the fittings will not be driven into the ground, but walled up in concrete, which will allow the wooden elements of the frame to last longer.

Why is a greenhouse open top?

Why is a greenhouse open top? Greenhouse "Butterfly", is it worth it?

Greenhouse "Butterfly", is it worth it? Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning

Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning Shed greenhouse, pros and cons

Shed greenhouse, pros and cons