Cultivators for inter-row cultivation of the soil - a necessary tool in the arsenal of tools of every gardener. Cultivation can be done manually, but it will take a lot of time and it will take a lot of effort. Cultivators greatly facilitate and simplify the process.

An agricultural unit for processing potatoes can have bonus extensions for additional functioning, in the form of replaceable elements - a rake or aerators. Since the emergence of the cultivator, the machine has been constantly improved in order to bring the gardener maximum benefit.

Content

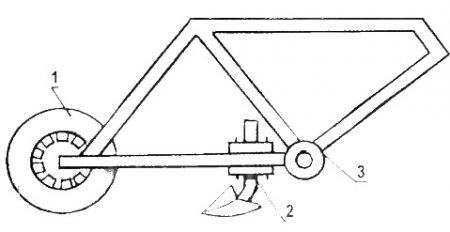

Homemade potato cultivator

After using the unit, the soil becomes loose, there are no dense lumps on it. In the future, fluffy and even ground can create better conditions for growing plants. Making a manual cultivator is simple and cheaper than acquiring a factory cultivator. You can make a homemade cultivator for processing potatoes from improvised materials. The convenience of such a tool is guaranteed.

Necessary materials

In order for the work on the creation of the cultivator to be as effective as possible, tools are used.

- Apparatus for welding with electrodes.

- Do not do without an electric drill with drills for metal and a gas burner.

- A tool for cutting pipe threads should be at hand.

- A set of locksmith tools along with a grinder will be useful, which will help to clean the welds.

The cultivator will be made of a metal sheet, the thickness of which should not exceed 4 mm, the sheet size on average should be 1 thousand mm X 500 mm. We will have to find a water and gas pipe, which is divided into two parts (one is longer, the second is smaller). You will need to use two steel bars of different diameters along with wing nuts and a full-bodied cylinder. The kit of the necessary materials also includes a crosspiece with four crosses, available inside the thread, four cotter pins.

Types of cultivators:

- In the aspect of the destination distinguish: row crop tools and steam. The latter is used before planting, and the first is suitable for hilling crops, removing weeds and loosening the soil.

- In terms of the working tool, one can distinguish: a milling machine or disk. There are options with lancet paws and an option for cultivating the land at a depth (chisel). Gardeners also use a ploughshare tool for processing plants.

- In terms of type of traction distinguish - mounted cultivator or trailed. Many gardeners still use manual equipment, while gasoline cars and even electric cars are available on the market.

- Considering the category of weight and power, they distinguish a light cultivator, heavy and medium. Thanks to new technologies, an effective ultralight model was created.

- Turning to the category of the number of rows processed, the cultivator can be classified as single-row or multi-row.

Rowing Mill

It is necessary to eliminate weeds, effective for loosening the soil and using material for fertilizer. For inter-row processing, milling cutters are used for crops such as cabbage and onions, beets and carrots, tomatoes, and not only potatoes.Nutrient compounds are stored in the soil treated with milling for longer, which contribute to increased productivity. As a result, gardeners have to use less herbicides.

Cultivating aisle of potatoes with a walk-behind tractor

Use a motoblock for different purposes. This versatile tool can weed and harrow weeds. Motoblock gardeners cultivate crops and plow the land. Owners of large land plots process them more often with a walk-behind tractor, which provides a person with a large coverage area. There are many videos on the network that are worth watching before processing potatoes with a walk-behind tractor. Gardeners before working with the unit must correctly assess the amount of work. Judging by the video, the inter-row processing of potatoes by the motor-block, judging by the video, is effective, while the mill for carrying out inter-row processing of the crop gives more freedom in maneuverability.

Cultivators for inter-row tillage:

- The KF-2.8 model, when it comes to row spacings, is ideal. It allows you to simultaneously fertilize, in addition to potatoes, soybeans, corn.

- The freezer model KF-3.6 in terms of cultivation efficiency is in no way inferior to the option described above, ideally loosening the soil and introducing material for feeding.

- The unit for loosening the soil and eliminating weeds USMK-5.4 is used to work with 12-row crops. This is a powerful tool capable of fertilizing row spacings up to 450 mm wide.

- The next model is an improved version of USMK-5.4, which comes with a supplement for feeding. It is possible to use mineral material in loose form with such an aggregate. This model equally well copes with both the processing of crops in 12 rows, and with the cultivation of crops with 450 mm row spacing.

- The considered model can be delivered in another form. Often gardeners prefer this tool with the addition of AVPU-12. Used by potato growers in the distribution of herbicides by tape. It is more efficient to use the model with AVPU-12 on crops in 12 rows. Many plants, including fodder beets and soybeans, get a great advantage from using such a device on the ground.

- The mounted cultivator KPH-4.2 is perfect for sowing crops in six rows. Row crops respond well to treatment with such a cultivator, it is suitable for row spacing in the range from 600 mm to 900.

- An effective hinged unit is considered the above model with the addition in the form of a feeding device. With this model, it is easier to apply mineral fertilizers on the ground with crops according to the 6-row scheme. The cultivator is effective on many row crops.

- The considered version of KRN-4.2 can be purchased from CASS. It is effective when using herbicides on 6 rows of seeded row crops, with row spacing of approximately 600 mm, or 700 mm.

- The hinged unit of the KRN-5.6 model is very popular. This updated model has proven itself in working on 8 rows with a different row spacing range. The weeds will be effectively trimmed, and an excellent level of cultivation after using this cultivator is guaranteed, as well as an even distribution of loose mineral material.

- For processing plants with row spacing of 600 mm, you can use the model KPH-5.6, equipped with a supplement feeding type. This is a great option when it comes to row spacings of 700 and 900 mm. Eight rows of crops can process the unit while at the same time filling in mineral fertilizing material and loosening the soil well.All weeds that interfere with the normal development of plants will be pruned.

- Traditionally, the KRN-5.6 model was released with an additional device. The model with CASS allows you to efficiently fertilize 8-row crops of row crops with the tape method of application, which gardeners use in the plots. As in the case of the predecessors, the cultivator, despite the addition, effectively fights weeds and evenly distributes loose fertilizer. The quality of loosening the soil remains at its best. The model may be more expensive compared to the previous two, but its efficiency in processing large sections is much higher.

Reviews

Alexey:

“I cultivated potatoes by hand all my life. Not so long ago I bought a plot with my wife more, we decided to grow potatoes for sale. On a large land, a cultivator is indispensable. They made the unit themselves from improvised means, but its efficiency compared to commercial was lower. We came to the conclusion that it was time to buy a good cultivator. We chose the KF-2.8 model. The quality of the soil after cultivating the land with this cultivator is at its best. ”

Yulia:

“You cannot underestimate the cultivation process - every gardener knows this. I consider myself an experienced potato grower, I always preferred to use a simple cultivator. But when it broke, the question was about buying a new one. My husband and I decided to invest in KRN-4.2. I never dreamed of a better treatment. The difference with the old cultivator is palpable. The result is excellent. ”

Lyudmila:

“We have two sites. On one we use a milling cutter for inter-row processing, and the second has to be processed with a walk-behind tractor to accelerate cultivation. Loosening the rows of potatoes with a walk-behind tractor allows you to speed up the work many times. I don’t know how we used to cope without such a miracle technique. It has become easier to grow potatoes, and cultivation with the help of a high-quality aggregate is largely reflected in yield. ”

Pauline:

“If you process 12-row crops, then it is difficult to find a better aggregate than USMK-5.4. This is a great model that allows you to quickly cultivate. The soil becomes light, fluffy. It easily passes air, which means that the plants on it develop better. There is no trace of weeds. It’s difficult to challenge the advantages of this cultivator compared to others. ”

Cover material for plant care: features of use

Cover material for plant care: features of use Types of winter covering material for plants

Types of winter covering material for plants Biohumus Farm

Biohumus Farm What covering material to choose for a greenhouse?

What covering material to choose for a greenhouse?