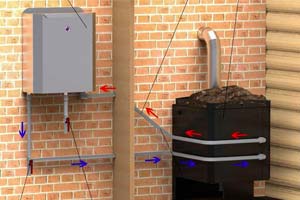

The arrangement of a suburban area today necessarily includes the construction of a bathhouse. And where is the bathhouse, there should be a furnace that quickly warms up the premises, giving “burning” steam. To build a bath stove with your own hands from metal with a water tank according to the finished drawings will not be difficult. There are many options, but most often the owners of the suburban area opt for metal stoves. You can not buy them, but do it yourself. Materials are available, the technology is understandable even to men far from technical issues.

The arrangement of a suburban area today necessarily includes the construction of a bathhouse. And where is the bathhouse, there should be a furnace that quickly warms up the premises, giving “burning” steam. To build a bath stove with your own hands from metal with a water tank according to the finished drawings will not be difficult. There are many options, but most often the owners of the suburban area opt for metal stoves. You can not buy them, but do it yourself. Materials are available, the technology is understandable even to men far from technical issues.

Metal bath stoves today belong to the safety class according to modern requirements, they are more practical than their predecessors.

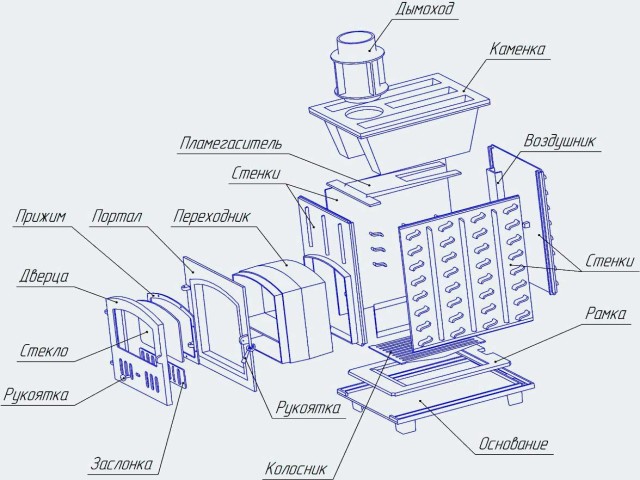

They are made of sheet metal 4 mm thick. The design of the new models includes special compartments, where stones fall asleep for a long time keeping warm. Almost all models have water tanks of different capacities in the structural structure. Making an oven with a water tank today has become a fairly common way to get excellent comfort in a steam room.

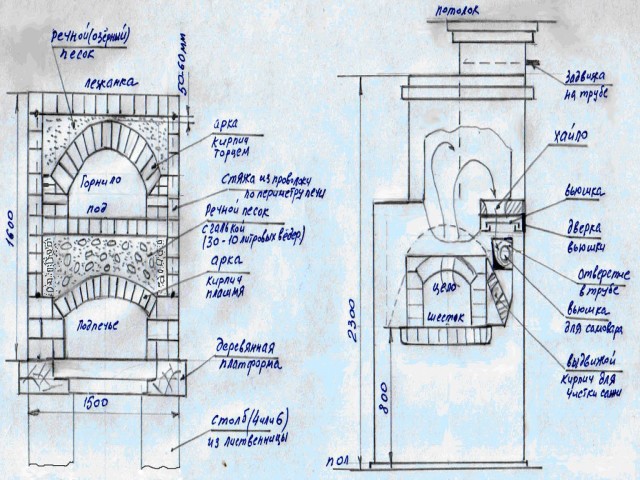

The furnaces have different constructive devices, and the home foreman always performs individual drawings in several projections, taking into account the structure of the bath. Her model involves the installation of two types of furnace structures: closed and open.

Content

Closed Furnaces

In the family bath, closed-type stoves are great because of their compact size.

To increase the heat capacity, it is recommended to enclose the casing on the outside and inside with refractory bricks, with the obligatory fixing of the brick with metal clips.

Brick lining will allow to heat with coal, while the usual design does not withstand coal heat, and it can only be heated with wood. The lined fire chamber significantly extends the operating time of the furnace from refractory steel.

In the middle of the furnace, a stone grate is structurally included.

To protect people from inadvertently touching the fiery surface of the metal, the side facing the steam room must be bricked.

Kamenka and bricklaying will be an excellent decoration of the steam room, give it individuality and comfort. Proper arrangement of the heating device in relation to the steam room will ensure heat preservation, excellent heating and light steam.

Open design furnaces

The main difference between furnaces of an open structural device is a small volume tank. The stove also remains open. When such a heating device is installed in the steam room, this ensures effective heating of the entire room. A simple method increases the heat capacity - the owner, when installing heating equipment, provides a galvanized lid for periodically covering stones.

A distinctive feature of the construction of a bath heating device is the use of a welded method for connecting metal parts of a structure. A photo and a drawing will help you make a metal bath stove with a water tank by welding yourself.

You will need a welding machine, an experienced craftsman with the skills to make high-quality seams. A highly qualified specialist, as the drawings indicate, will weld a tank of boiler iron, equip it with a tight lid, a faucet of a special device.The faucet and lid entries must allow tank cleaning.

The secret to installing a drain tap. The tap entry must be inserted at the bottom of the tank. A fitting for attaching a removable crane is mounted directly to the tank by welding. This will make it possible to clean the tap in a timely manner. It is recommended to use a ball type valve.

Combined Design Furnaces

In the case of combined furnace designs, a firebox with two valves is arranged - this is their main feature.

The lattice, nozzles with a diameter of 10 and 14 cm, and a blower are included in the constructive structure. Such kiln structures suggest the use of 5 mm thick hardened steel sheets in their manufacture. With your own hands, you can make a metal bath furnace, equip it with a water tank, a convenient tap to completely drain the water for cleaning the tank.

Combination-type furnace bath designs are a simple budget option. They are heated with wood, saturating the steam room with the invigorating aroma of burning wood.

As you can see, making a do-it-yourself metal stove for a bathhouse with a combined water tank is not so difficult if you have drawings and videos with you.

Read also:

Time to design a bath stove

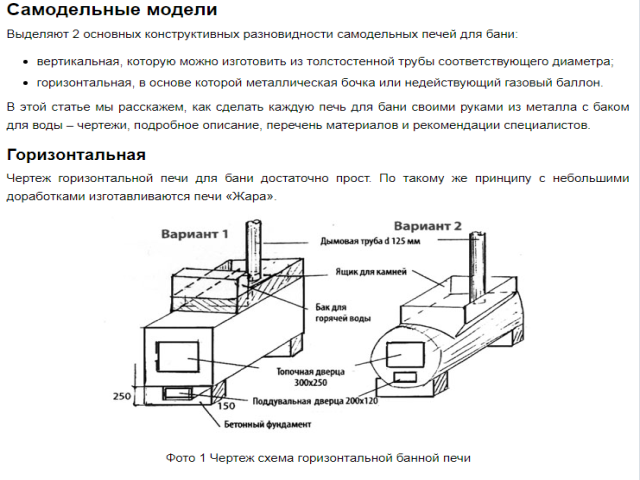

The stove model of special parts — pipes and barrels — is most acceptable for doing it by hand, if there is source material of the corresponding parameters. The home foreman should first consider whether the planned stove is suitable for the size of the bathhouse under construction, carefully draw all the drawings to get an excellent result.

It is important to choose the location of the heating complex, and take into account in its size all the necessary components:

- firebox;

- heater;

- grate;

- chimney;

- valve;

- water tank;

- ring-shaped steel coupling.

In the roof of the building, it is necessary to foresee a hole in advance where a pipe will be drawn for the removal of smoke. Therefore, the furnace model, especially performed independently, should be thought out simultaneously with the design of the bathhouse.

Variety of shapes

Form is an essential factor in solving the issue of heating performance, ease of use and design of a steam room.

Oven designs of various shapes are used:

- rectangular;

- horizontal

- cylindrical;

- curly.

Rectangular heating devices are considered more convenient for use. The secret lies precisely in the presence of angles that during operation do not heat up, ensuring maximum preservation of the shape of the entire structure for a sufficiently long time. In addition to a long service life, the furnace form provides uniform heating, reduces heating of the entire wall. Because of this, the whole room is warmed up as much as possible, a uniform balance of heat flows is ensured. Proper heating increases the service life of the furnace, due to the corners it has high indicators of mechanical stability.

The cylindrical and round furnace structures are least able to withstand the high temperature effects. Therefore, for their walls, craftsmen use more dense and reinforced material.

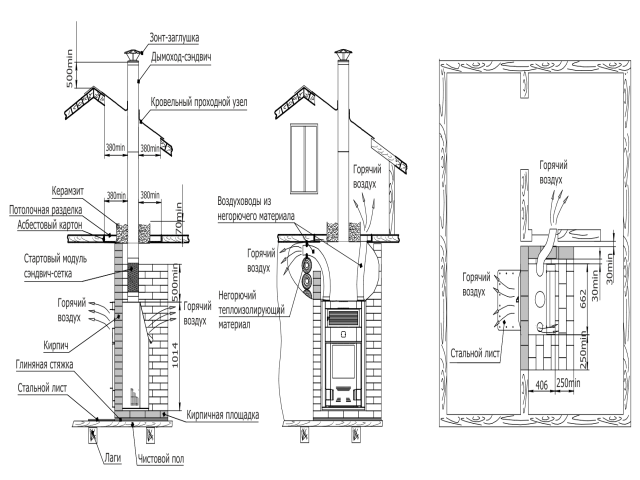

Installation of the furnace in the bath

The sauna stove is located either so that the furnace door goes into the next room, or directly in the steam room, where firewood is laid. This moment is considered at the design stage, which is important in choosing a furnace model.

The first stage of mounting a metal heating device is laying the foundation. For it, a brick with high refractory properties is used, fastened with a mortar of high quality concrete.

The brick is laid out necessarily in several rows.If the furnace building is not planned to be bricked, then it should be installed at a distance of not less than 1 m from the wall. All installation conditions are laid down in the drawings developed by the designer or the home foreman himself at the stage of preparation for the construction of the bathhouse.

The furnace is installed on the foundation only after it finally hardens - this is a prerequisite for the installation of a metal structure. If the bathhouse is located separately from the residential building, then due to its small size, it is subject to temperature changes. For this reason, a shallow foundation is laid, especially strong and frost-resistant.

The furnace is installed on the foundation only after it finally hardens - this is a prerequisite for the installation of a metal structure. If the bathhouse is located separately from the residential building, then due to its small size, it is subject to temperature changes. For this reason, a shallow foundation is laid, especially strong and frost-resistant.

It is recommended to cover the section of the wall near which the heating device will be covered with foil insulation material - this will be an additional reflection of heat and excellent protection of the building’s fire.

This applies only to structures made of metal, not lined with stone.

When the design of the furnace structure should be located a little closer to the wall, then cladding with bricks is a mandatory requirement for fire safety. If the metal furnace is sheathed with brick, the dimensions of the sheathing must be observed - height 120 mm, width 80 mm. If these dimensions are exceeded, the brick warms up for a long time, does not give enough heat to the steam room. Such a detail is necessarily indicated in the drawings and is visible on the photo-instructions for the manufacture of a furnace for a metal bath. Brick cladding provides additional operational safety, gives the room an aesthetic appearance.

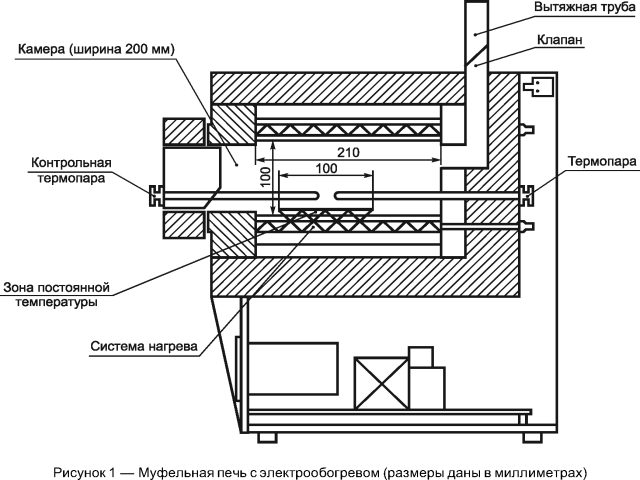

Important points of the chimney

The metal heating complex should include a well-insulated chimney. For their device, it is recommended to use a pipe sandwich with a special heat-insulating layer in the structure between the outer and inner casing.

The ceiling passage unit is equipped at the junction of the ceiling with the pipe, this provides the possibility of the exit of combustion products.

The secret to warming the chimney. A metal bath stove includes an iron chimney in its structure. It is performed in a welded manner, from special pipes. By melting the stove in the cold room of the bathhouse, the owners often observe smoke, and poor burning. To avoid this, it is recommended to warm the chimney, burn at least 0.5 hours in the furnace for at least 0.5 minutes, and then start the usual kindling.

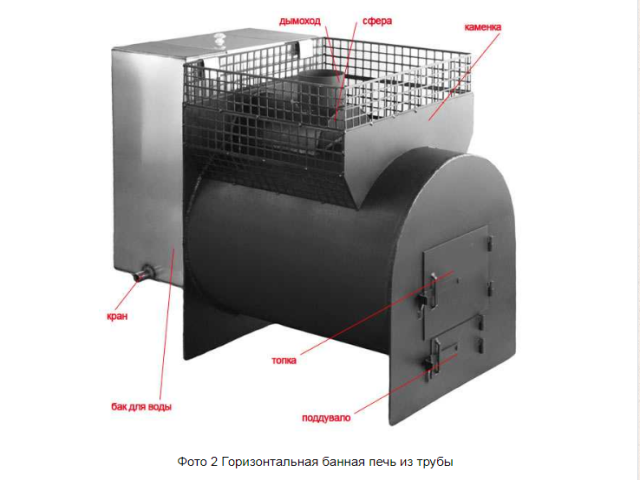

Furnaces for a bath of vertical and horizontal type

You can independently build metal structures with a different arrangement of the furnace - vertical and horizontal.

A horizontal furnace is included in the structure of the furnace with a tank, a vertical furnace is included in the structure of the furnace, made of large diameter pipes.

A tube furnace is more resistant to high temperature, burns out less than a furnace with a tank, and therefore lasts longer.

Stove heating allows you to set humidity and temperature indicators in a steam room, air from burning firewood is of great benefit to the body when firewood of the same species is used - birch, oak or coniferous trees.

A stove for a bath with a tank for heating water and a pocket-heater creates a comfortable atmosphere in all bath rooms, and its external design can become an exclusive “highlight” that reflects taste preferences if you make it yourself, using our tips, videos and drawings.

Why is a greenhouse open top?

Why is a greenhouse open top? Greenhouse "Butterfly", is it worth it?

Greenhouse "Butterfly", is it worth it? Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning

Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning Shed greenhouse, pros and cons

Shed greenhouse, pros and cons