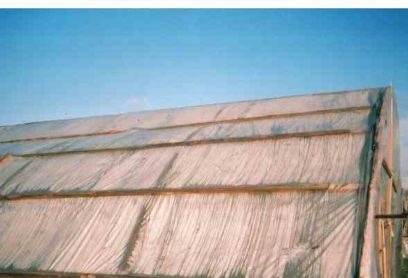

To save the area of your personal plot and not spend a lot of money on the construction of greenhouses. One of the great options is an economical and easy to install stretch film design.

It is light in weight, well tolerates transportation and movement around the site. It is especially suitable for small suburban areas where it is not possible to install several greenhouses.

Content

Advantages and disadvantages

The appearance of this film was not used as a covering material for greenhouse constructions. Now it is popular among gardeners and gardeners. She has several advantages.

The appearance of this film was not used as a covering material for greenhouse constructions. Now it is popular among gardeners and gardeners. She has several advantages.

- Serves two to three years.

- Not subject to damage.

- Good thermal insulation properties. Helps to maintain the humidity required for plant growth.

- When mounting additional equipment and fasteners are not needed.

After a full installation, it is clear that there are no differences from other types of structures. Structures from it weigh a little. When wrapping between layers, air space forms. This helps to keep the heat indoors and helps to neutralize the negative effects of sunlight. It transmits ultraviolet rays, which, in the end, get plants and ripen on the vine in a shorter time.

During construction using streych material, it is possible to avoid the use of additional fasteners. It is quite elastic. Using it, you can create any design, and it will not harm it, since it has a low weight. The construction of such facilities is very fast.

What are the negative properties?

- Since the air in a room with such covering material heats up instantly. Plants do not tolerate heat and direct exposure to sunlight.

- Sashes and vents using stretch film are difficult to mount.

- Designs with this covering material quickly lose their pristine beauty.

- Stretch quickly gets dirty, so you need to wash it regularly.

The foundation for the greenhouse

To build greenhouse using stretch film to build a foundation is not necessary. For example, if you use wood to install the frame, then to completely strengthen the structure, you will need to install a simple base of ceramic bricks or wooden beams. If a framework made of propylene pipes is used, a good soil compaction is sufficient.

For structures more than one and a half meters in height, it is best to use an additional frame mount so that your greenhouse is not blown away by gusts of wind.

Greenhouse frame material

The foundation decides a lot. The stability of the entire structure and resistance to negative weather factors depend on it. From this we can conclude that during the choice of building material for installing the frame, weather is taken into account.

The foundation decides a lot. The stability of the entire structure and resistance to negative weather factors depend on it. From this we can conclude that during the choice of building material for installing the frame, weather is taken into account.

- Frame made of wood. This building material is often used in construction. The price is many times lower. But! It requires constant care and additional processing from insects and rot.

- Frame made of metal and steel. These materials give reliability and durability. He has been serving for several years. It is enough to paint and treat the racks with anti-corrosion compounds.

- Aluminum frame.It weighs a little and is more durable than the first two materials. Additional care is not required, it is enough to carry out preventive measures.

The choice of stretch film

The main factor in choosing the right stretch film is the thickness and resistance to external factors. The table shows the main parameters by which you can compare its types:

| Film type | Thickness | Resistance to external factors |

| Kling | 5-11 microns | Low, easily torn |

| PVC | 20-30 microns | Medium, torn with effort, but passes heat |

| EVA | 13-20 microns | High, has the best thermal insulation performance |

| Polystyrene | 7-18 microns | Medium, torn with effort, but has less elasticity |

As cover material is better to choose PVC As you can see from the table, the Kling film is thin. To cover the frame of the greenhouse, it will take 7-8 layers.

In order to avoid mistakes in working with it, it is worth paying attention to what type it is. For example, polystyrene is poorly stretched unlike polyvinyl chloride. It can stretch three to four times. It does not lose its properties.

Design selection

The best type of design is an arc shape. It is assembled using support elements vertically. In height, it can be completely different. In this case, the thickness is selected individually. This type of greenhouse does not need additional construction of the base and roof. A damaged item can be replaced individually.

The best type of design is an arc shape. It is assembled using support elements vertically. In height, it can be completely different. In this case, the thickness is selected individually. This type of greenhouse does not need additional construction of the base and roof. A damaged item can be replaced individually.

Also do not forget about the weather in the region of your residence. Here it is necessary to take into account what level of snow in winter. It is the design in the form of an arc that will allow avoiding large loads both on the base and on the covering material itself.

You may be interested in:

You may be interested in:Calculations

In order to correctly determine the amount of building materials that will be required to erect a greenhouse from a stretch film, it is necessary to take into account its main parameters.

- What vegetables will be grown in the greenhouse. Since its height should be more than about one and a half times the height of plants.

- The calculation of the number of supporting elements depends on the length of the greenhouse. So, for 2-3 meters, the installation of one support is required.

- The presence of the foundation. If you do not install the lower harness of the greenhouse or do not build the greenhouse, then the length of the support should be 50-60 centimeters longer. This is necessary to immerse it in the ground.

- A two-layer coating of frame elements is ideal. That is, after a complete calculation of the area, add 1/3 of the part, since it is used for overlapping and double the resultant value. To protect plants from winds and drafts, the "Skirt" is used, which accounts for approximately 15% of the obtained length. And then we divide the obtained value into two, taking into account the stretching of the film material.

Greenhouse assembly

Mounting a greenhouse from stretch film begins with the installation of the frame. In the case of choosing a building material in the form of arches made of propylene, they are initially dug into compacted soil. If necessary, it is necessary to complete the binding of the frame from the bottom. A timber beam is laid around the perimeter and vertical supports are attached using clamps and corners.

Mounting a greenhouse from stretch film begins with the installation of the frame. In the case of choosing a building material in the form of arches made of propylene, they are initially dug into compacted soil. If necessary, it is necessary to complete the binding of the frame from the bottom. A timber beam is laid around the perimeter and vertical supports are attached using clamps and corners.

The frame of metal and wood is usually assembled from the opposite. In other words, the end walls are assembled, after tying the lower part, then vertically directed supports and then the strapping in the upper part.

To make the winding of the finished frame, you do not need to disassemble or remove it. Winding should begin with the upper parts of the structure.

The most difficult to assemble the door and window. For this, the stretch film must be attached to the frame using a building stapler. Next, attach the door with a glazing bead, attaching all layers of stretch film. Also do with a window leaf.

Tips and bugs

For the construction of a full-fledged greenhouse, there are certain tips that will help to avoid mistakes when mounting greenhouses using stretch film.

- This type of film is attached to various surfaces.

- Before stretching the film, check the frame for strength.

- Avoid bumps and nicks in the material used to build the greenhouse frame.

- Before coating the film, process the frame with grinding equipment.

- Do not leave the elements of the greenhouse with one layer of film.

- Note that stretch film is prone to destruction from exposure to sunlight.

- The height of the greenhouse and the effect of wind on it. At a height of more than one and a half meters, additional reinforcement in the form of diagonal elements is required. So, the impact of wind will be minimized.

You may be interested in:

You may be interested in:It is easy to assemble a greenhouse design using a stretch film as a covering material. It is enough to follow the instructions and avoid blunders. Such greenhouses have proven themselves on the positive side among summer residents and gardeners - gardeners. They save not only the family budget, but also time. Compliance with temperature and humidity has a positive effect on the growth of cultivated plants. As a result, they will pamper you with an excellent harvest at the end of the season.

Why is a greenhouse open top?

Why is a greenhouse open top? Greenhouse "Butterfly", is it worth it?

Greenhouse "Butterfly", is it worth it? Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning

Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning Shed greenhouse, pros and cons

Shed greenhouse, pros and cons