You can build a wooden barn if you do everything step by step and strictly according to the instructions. Here, of course, themed video and preliminary preparation will help. A frame wooden shed is inexpensive if you consider the bills for materials, while constructing it yourself is quite simple, you only need to prepare in advance and allocate time for this.

You can build a wooden barn if you do everything step by step and strictly according to the instructions. Here, of course, themed video and preliminary preparation will help. A frame wooden shed is inexpensive if you consider the bills for materials, while constructing it yourself is quite simple, you only need to prepare in advance and allocate time for this.

Before you start building a barn, you need to do some preparation. You need to understand exactly where the economic block will be located on the site. Here you should not choose a prominent place for construction, the far corner of the site, the space behind the houses or near the fence, is perfect. Pay special attention to the fact that the passage to the barn should be free: do not clutter this place, do not break beds or flower beds there.

Content

Tips for choosing a good place where to build a do-it-yourself barn:

- The hill is perfect for the construction, which immediately protects it from spring floods, heavy rains. The design on such a site will serve for a long time.

- When choosing a project and approving it, you need to immediately determine the width of the front door: it must necessarily be suitable for the particular car used by the summer resident for garden work.

- You can take any materials for work, it looks great and is convenient to operate a shed from boards, timber. Under the base, you can safely choose a prefabricated or columnar, even monolithic foundation.

- As for the final form, there are also no strict rules and it is worth choosing structures that are suitable for your needs. The easiest way to build gable shed, but other types of roof are also acceptable, it all depends on financial capabilities.

About the benefits of a frame shed

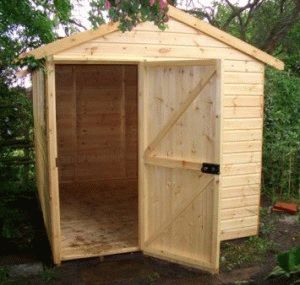

A step-by-step instruction shows that in the matter of how to build a shed, the frame option is good due to the fact that you can buy ready-made parts, and then just quickly assemble the structure. It is not difficult to implement such a project independently, and even a beginner in the construction business can cope with work. At the same time, the design turns out to be durable and, if you select the right place for it on the site, then you can use the shed for many years without problems.

A huge plus is the speed of construction. The construction manual suggests that for work you need bars, boards, nails and metal corners, as well as about a week of time for all work. Additionally, you do not need to make a rafter system!

Putting the foundation together

A phased plan for the construction of such a structure can be seen in the video for this material. However, some extremely important initial stages of work are also being built to give more attention to. Moisten the soil under the shed and additionally tamp. Repeat the procedure several times, it is necessary to ensure that the soil gives complete shrinkage.

Advice! Using a long level, you need to additionally check how smooth the soil surface is. When this fact is precisely established, you can move on to construction.

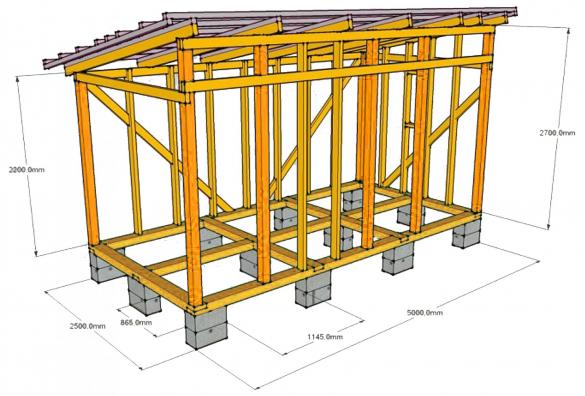

From above, pour sand and gravel pillow onto the ground and compact it with an additional one. Mark out approximately the outline of the future barn. Install concrete blocks at the corners of the perimeter. A wooden frame is assembled on these blocks (secure with anchors by making holes in concrete blocks). Separately collect lags for the floor, remember that part will go under the walls.The floor must be well insulated, this is also an important stage that should not be ignored.

Which floor insulation to choose:

- Mineral wool is considered widespread and easy to install, its important advantage is its low price. Cotton wool is usually sold in packages. Put it on a layer of roofing material or ordinary plastic film. Neatly lay mineral wool slabs in the floor compartments. In addition, it is recommended to treat the floor logs with impregnations from rotting, special antiseptic agents. You can put a layer of several plates to insulate the floor more, but you can not ram the material, because it quickly loses its heat-insulating properties.

- You can also use polystyrene to warm the floor in the barn. For its installation, you will also need a wooden crate, then put a layer of waterproofing. The material is convenient to work because, it does not deform, over time it does not bother fungi or mold. The slots that remain between the plates can additionally be repaired using a mounting foam.

- Expanded clay can also be used to warm the floor in the barn, for this you need to make the lower formwork and provide a layer of waterproofing. Expanded clay will need to be poured into each section obtained in the formwork. The layer of this material should be up to 15 cm, otherwise, thermal insulation will be poor. This material must additionally need to be leveled, it should not be higher than the crate with bars.

Walling

To build walls you need to use the corners of the pillars that were made for support. In addition, everything is necessarily checked by the level, after which it is securely fixed. Pillars are attached to the frame using special angles, then strapping is done from above. A columnar foundation is made around the perimeter of the selected rack. We remind you that, in principle, for such a business unit, you can choose any type of foundation.

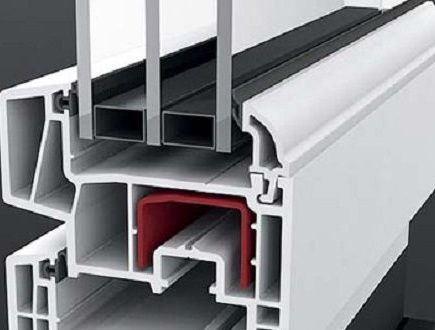

Finishing work is done taking into account the installation of doors and window frames. It is clear that the shed does not have to have many windows, but still, the light should go there. Be sure to do the outer skin, for this board are lapped. Separately, you should think about insulation from below, experts in this case, it is recommended to use membrane insulation. You can use a profiled board for warming from below.

Inside, the room also requires additional cladding. The walls should be insulated, waterproofed, and then use fiberboard or chipboard for cladding, which allows the budget and a sense of personal taste. It often happens that this building is used not only as a barn for storing things, but also as a place to work. In such a situation, it is recommended to additionally sheathe the lining inside.

Advice! If it is not necessary that the room is warm all year round, covering in one layer is sufficient. When you want to get a thermal structure as a result of construction, you should use two-layer cladding.

Built barn, the main material for which was wood - it is convenient and practical. If a person is completely new to construction, then you should definitely prepare for the construction of such a structure by reading additional materials on our website and, of course, by carefully watching several thematic videos. It is worth mentioning separately some of the shortcomings of the wooden structure. Let them be few, but still there are such. First of all, one should never forget that wood is a material that burns actively and well.

Like any natural material, a tree rots and there is a chance that various insects will gnaw at it.In principle, modern construction methods can minimize such shortcomings; it is possible to impregnate a tree with antiseptic pastes, organic solutions, or traditional oil-based antiseptics even at the stage of construction construction. Wood lends itself to moisture and, under the influence of moisture, can dry out, swell and warp over the years.

Why is a greenhouse open top?

Why is a greenhouse open top? Greenhouse "Butterfly", is it worth it?

Greenhouse "Butterfly", is it worth it? Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning

Do-it-yourself landscaping of an area of 8 acres: features of planning and zoning Shed greenhouse, pros and cons

Shed greenhouse, pros and cons

Alexander

Why insulate the floor in the barn?